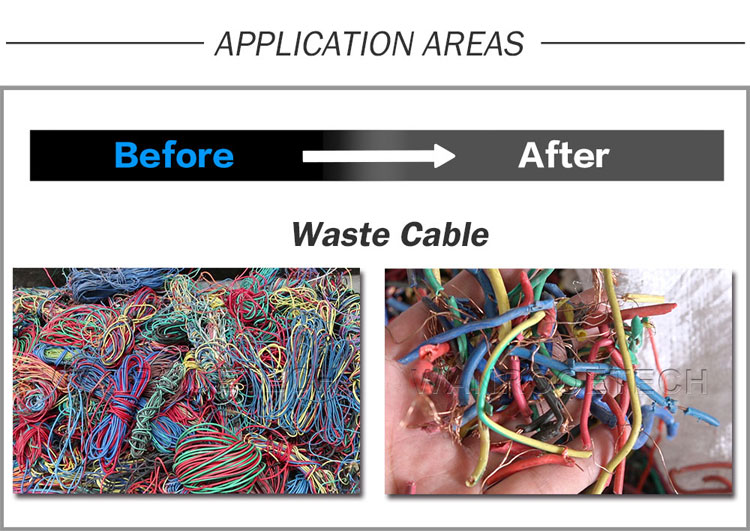

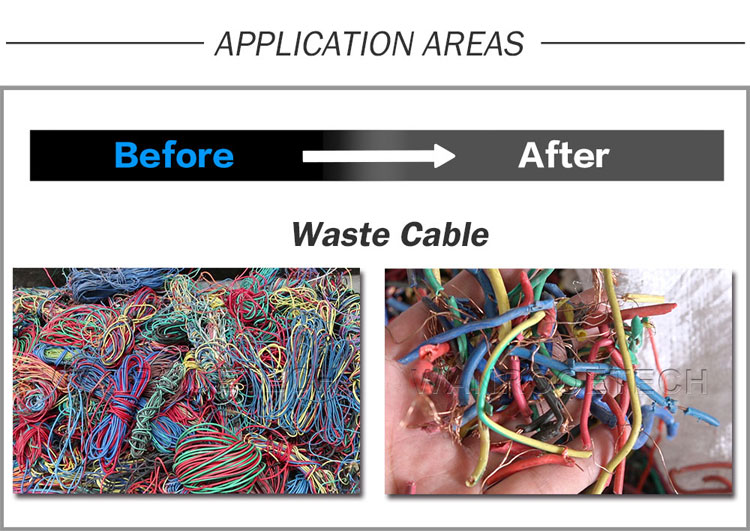

Scrap Cable Shredder Copper Wire Shredder Application Areas:

Scrap Cable Shredder Copper Wire Shredder can shred Waste communication wire, wire and cable, automobile wire, computer wire, telephone wire, USB data wire, household appliance wire, and other wires.

Why recycle copper cable?

Approximately 60 to 80% of the weight of cables comes from the metal contained inside it. The main driving force to recycle cable waste is to recover the valuable metal portion. Copper is also a non-renewable metal whose exploitation incurs serious environmental effects. Such metal after recycling doesn’t degrade, thus it can be recycled indefinitely. Every day a great amount of broken, unused and aged cables are discarded worldwide, taking up a large portion of e-waste. Accumulation of abandoned cable posts potential fire hazard which can bring harmful effects on nature and human beings. It makes great sense to recycle waste copper cables.

How to recycling copper cable

The decisive step in cable recycling processes is the possible entire separation of the metal fraction from the plastic insulation. A typical scrap cable recycling line consists of a combination of different shredders, granulators for material reduction and disintegration, as well as separation lines for separating metal from the plastic part. The reclaimed metals and plastic are then melted and reused to make new products.

WANROOETECH copper cable shredder for your copper cable recycling

WANROOETECH focuses on providing professional size reduction machinery. We offer all types of size reduction machines with a wide choice of different cutting knives, screen mesh sizes and output capacity to meet your specific requirements. Based on the different type and sizes of copper cables to be shredded, the shredding capacity required, the final output shred size required, etc., our sales representative together with our engineer team will analyze and propose you a most suitable and cost-effective solution to suit your need.

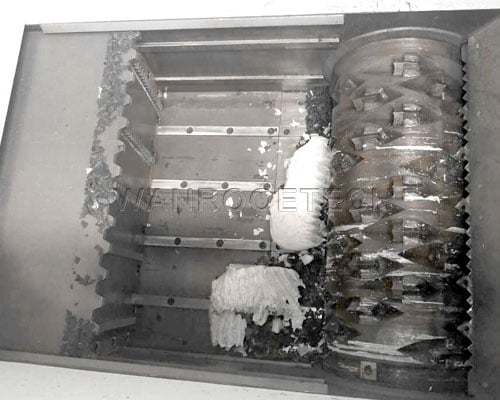

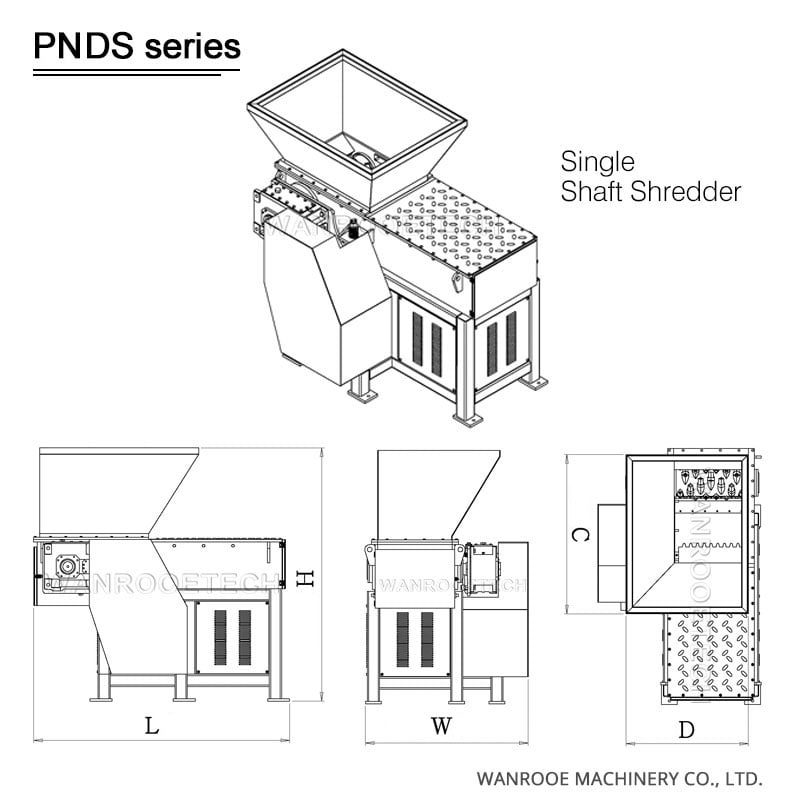

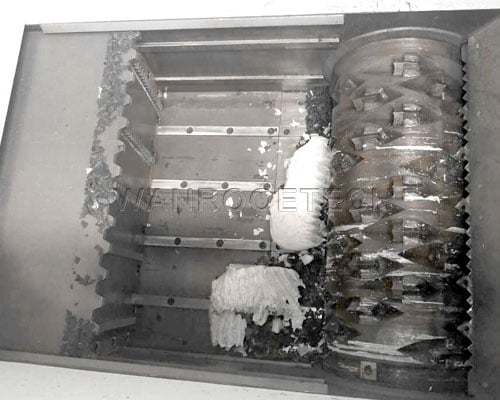

Single shaft shredder Blade:

Scrap Cable Shredder Copper Wire Shredder Components:

|  |

Pusher System Reinforced baseplate can reduce the impact caused by material entering the cutting chamber. A dust collection device is equipped at the bottom of the pusher system to guarantee the long-term stable performance of internal components. | Heat treated rotor knives Special DC53 steel (hardened) four edges use before the replacement |

|  |

V-cutting rotor design with staggered cutter positioning |

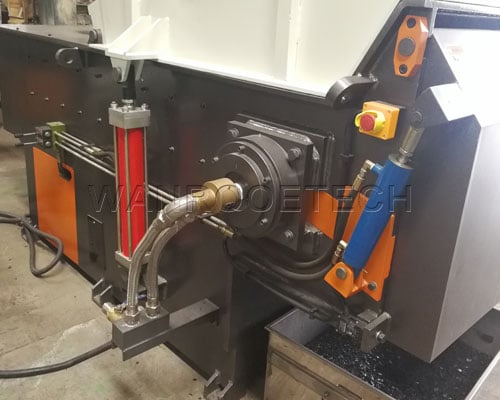

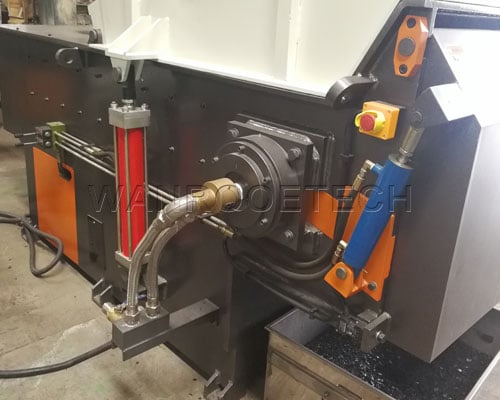

Cooling systems water-cooled and air-cooled systems. In the Middle East and North Africa, where the temperature is particularly high, water cooling is required; in other less hot countries, such as Chile and Northern Europe, air cooling is sufficient |

|  |

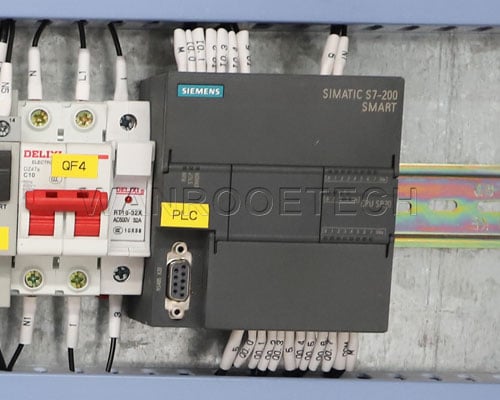

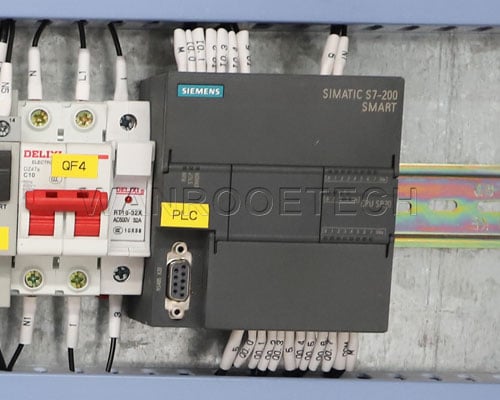

Control panel Equipped with independent and reliable electrical control panel like SIEMENS PLC control system, DELIXI contactor, SCHNEIDER Electric, etc.

Manual & automatic operational modes to choose, quite flexible and safe.Motor overload protection.

| Screen Unit Wide range of screens with a variety of configurations and mesh sizes are replaceable based on customers' production requirements. The paper shredder will automatically stop while opening the screen unit to ensure operator safety. The screen is produced and mounted in sections, allow for easy maintenance. |

|  |

PLC control Making it easier for fault diagnosis and maintenance. | Hydraulic Station The pressure and rate of flow can be adjusted according to different materials. |

Scrap Cable Shredder Copper Wire Shredder Features:

1)Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power slewing axis; Big hopper with big caliber for feeding big material

2)PLC control system with automatic overload protection and auto-reverse switch

3)Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4)Each dynamic blades has four cutting edges which enable reutilization after being abraded, by rotating 90 degree

5)Each fixed blades has two cutting edges which enable reutilization after being abraded, by rotating 180 degree

6)Quiet operation at low speed

7)Screen perforation is adjustable according to customers' requirement

8)The shredders can be adjusted according to customer-specific requirements for throughput volume, material to be processed, etc.