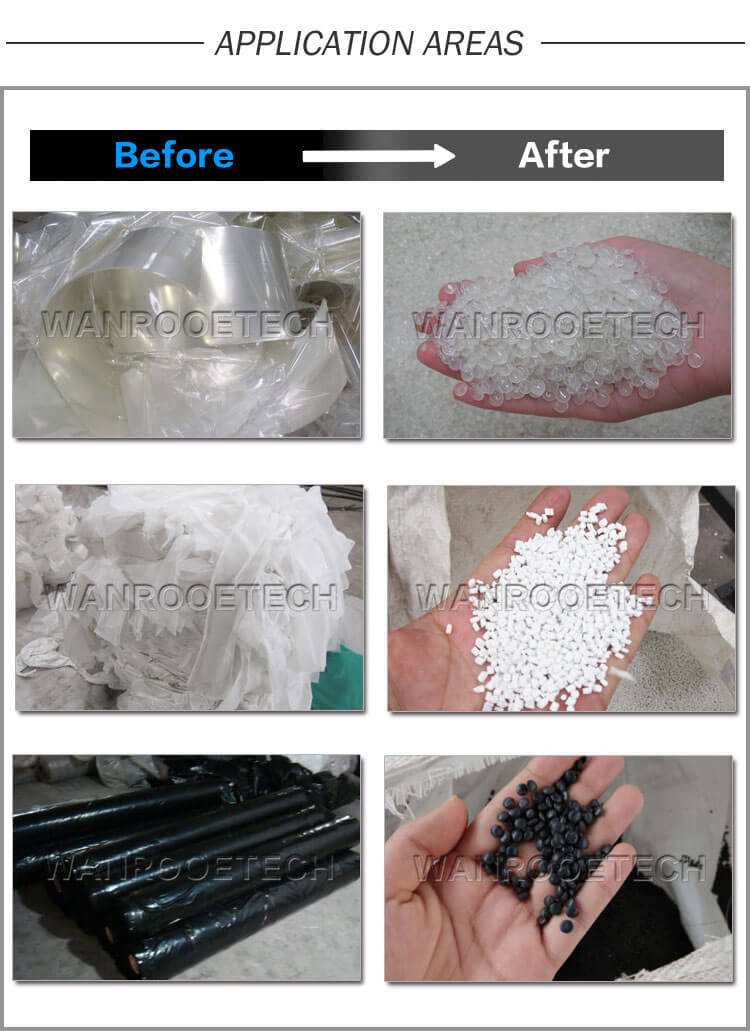

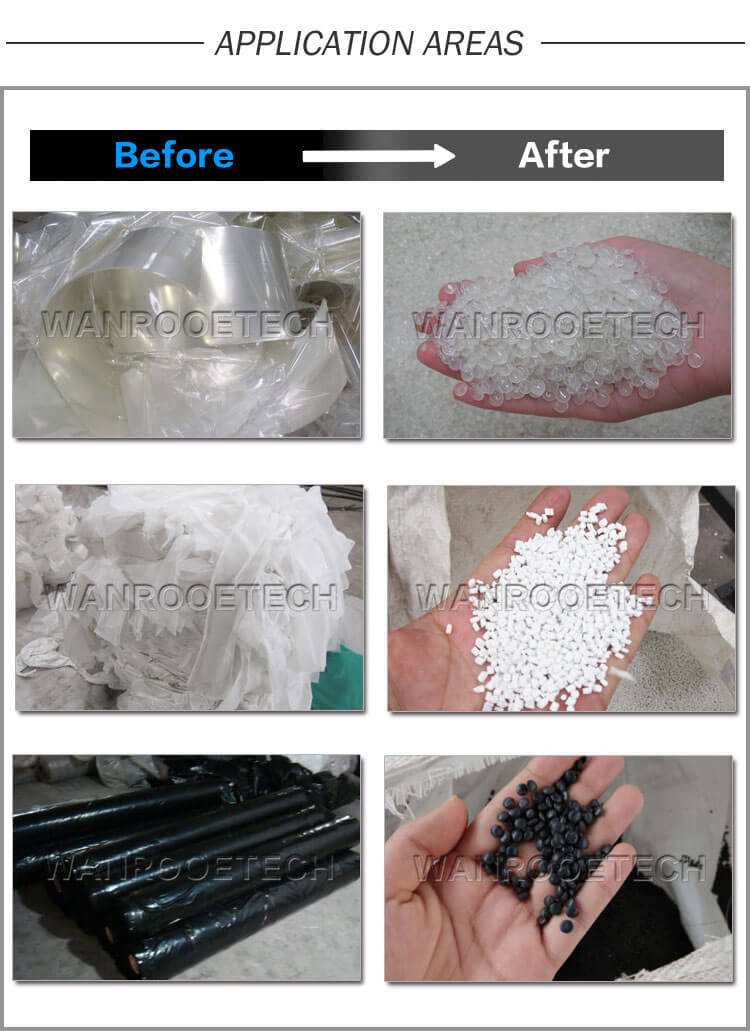

Waste Plastic Film Recycling Pelletizing Machine Application:

PP PE waste plastic film recycling pelletizing machine with international advanced recycling technology and combined with the actual application condition. This plastic film pelletizing recycling machine is design specializes for recycling the washed plastic PE film, such as PE plastic bags, plastic packing films, plastic shopping bags, agricultural film etc.

After PE PP plastic film pelletizing machine processing, the final products are plastic pellets/granules, which can be to produce plastic bags, drainage pipes, plastic board/sheet etc.

Waste Plastic Film Recycling Pelletizing Machine Description:

This waste plastic film recycling pelletizing machine is one stage plastic regenerative pelletizer, which is suitable for many kinds of plastic waste materials recycling and making pellet, such as PP, HDPE, LDPE, LLDPE Film and clean woven/nonwoven bag materials, etc. The film can be pressed in the compressor and then be pelletized.

Waste Plastic Film Recycling Pelletizing Machine Process flow:

Conveying feeding→ Metal detector →Film Agglomerator /Compactor →Degassing single screw extruder →Hydraulic filer exchanger→ Mould head →water ring cutting →Dewatering machine→ Air dryer Blowing system→ Storage hoper→ Finished product packing.

Waste Plastic Film Recycling Pelletizing Machine Components:

|

|

Conveyor (with metal detector) Metal detectors can be combined with belt conveyors, and can interlock with the control system, to warn and stop the system, in case that metal is found in feeding. | Agglomerator Agglomerator combines pre-heating, pre-dry and size reduction to ensure a fast and stable feeding process. |

|

|

Single Screw Extruder Our unique design single screw extruder gently plasticizes and homogenizes the materials. Our bi-metal extruder has great anti-corrosion resistant, wear resistant and long life time. | Full Auto Hydraulic Screen Changer With Double Working Position Long screen lifetime, lower screen change frequency: Long filter lifetime owing to large filter areas. Easy to use and none-stop type: easy and quick screen change and do not need to stop the running machine. |

|

|

Water Ring Pelletizing System Cutting the material into pellet. Water ring pelletizing system set as the standard granulating method. self-adjusting pelletizing head for the best granulate quality and long uptime thanks to consistently correct blades pressure. | Dewatering And Air Sending System Horizontal type centrifugal dryer to get well-dried final granules. |

|

|

Electronic Control The whole model adopts frequency conversion control and conforms to international standards such as CE/CSA. | Silo Storage the final pellets in a bag. |

Detailed description of each item:

1. Conveyor: convey PP PE film or flakes into compactor.

2. PE film Agglomerator /Compactor: crushing and compress film, and feed compressed film into extruder forced, to make the production capacity high and stable.

3. Extruding system: plasticizing material and exhausting gas.

4. High speed Net exchanging system and Die-head: filter material impurity, to make production more stable.

5. water ring pelletizing machine: cutting pellets in water.

6. Water tank: cooling pellets.

7. Dewater machine: make pellets dry.

8. Vibration sieve: remove bad pellet and keep good pellet.

9. Air Blower: convey good pellets into silo.

10: Storage silo: keep pellet.

Equipment List:

| 1 | Belt conveyer (can equip the metal detector ) |

| 2 | Agglomerator /Compactor machine |

| 3 | Extruder |

| 4 | Die head and screen changing device |

| 5 | Water ring cutter |

| 6 | Vibrating screen |

| 7 | Vertical dewatering machine |

| 8 | Air drying system |

| 9 | Cyclone hopper |

Waste Plastic Film Recycling Pelletizing Machine Features:

1. Allow free assembling of the screw component, based on raw material type.

2. Using the suitable die head for palletizing, such as water ring cutting, under-water cutting and hot face cutting.

3. High efficient force feeder ensures stable high capacity material feeding, low power consumption.

4. Main screw has vacuum exhaustion.

5. Water ring granulator machine, attached with dryer.

6. Single screw extruder, with a specially designed screw, barrel, venting system, ensures the good quality of the final products.

7. Pelletizing style: standard cutting with extrusion mould. Even cutting ensures good shape.