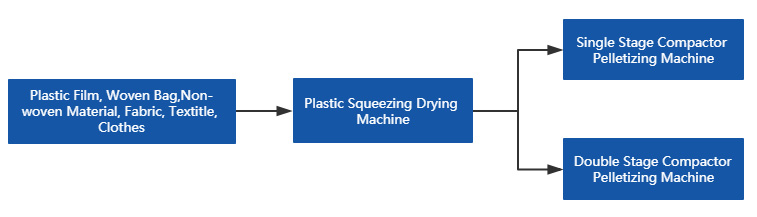

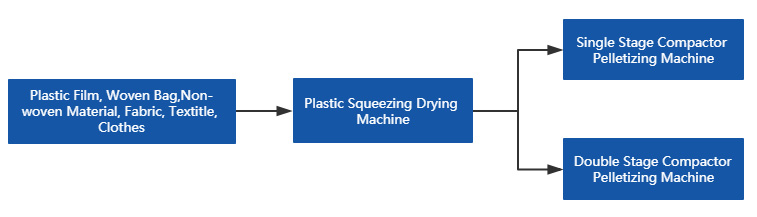

Plastic Film Woven Bag Screw Press Squeezing Dryer Machine Application:

PP PE Film, Woven Bag Plastic Squeezing Drying Machine is used for squeezing and re-pelletizing PP/PE film, woven bag, ton bags, nylon etc. it's equipped with advanced screw extrusion system, squeezing efficiency could reach 95%. Also can work on the accordance with washing and pelletizing line with stable capacity and whole process automation.

1. LDPE waste film recycling and washing line

2. PE agriculture using films crushing and washing line

3. Waste PE film recycling line

4. Ethylene ground film washing, drying and regranulating line

5. Waste film recycling and washing line

6. PP woven bag recycling and washing line

Plastic Film Woven Bag Screw Press Squeezing Dryer Machine Description:

Plastic Squeezing Drying Machine is used for remove the water in plastic after washing. No hot air required compare to centrifuge, it consume less power, you can get good drying effect without a hot air system, less waste of materials, as materials will be thrown out from centrifuge, which is big waste.

There are three types for you choose:

1. Jaw style, control the outlet pressure to adjust the drying effect.

2. Breaking style, with a removable device to control the pressure and break the materials.

3. Hot melting style, with heating part to make the materials to semi-melting grade to get a better quality effect.

Plastic Film Woven Bag Screw Press Squeezing Dryer Machine Components:

|  |

Squeeze Screw

The screw is a whole round steel raw material cutting, no welding, the material selected is 38CrMoAi senior nitride steel. It has the characteristics of anti-wear and anti-fatigue, high strength, etc. After processing and forming, it is nitrided, quenched and straightened for several times. | Barrel

The barrel is also cut from whole round steel without welding, and the material chosen is 38CrMoAi high grade nitride steel. It has the characteristics of anti-wear and anti-fatigue, high strength, etc. After processing and forming, it is nitrided, quenched and straightened for several times. |

|  |

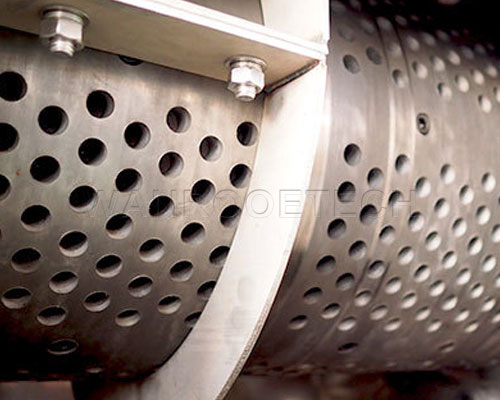

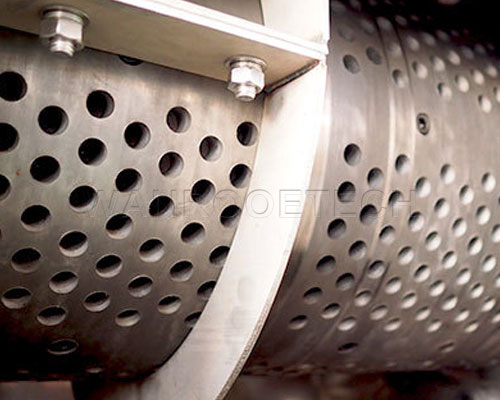

Bottom Leaking Groove

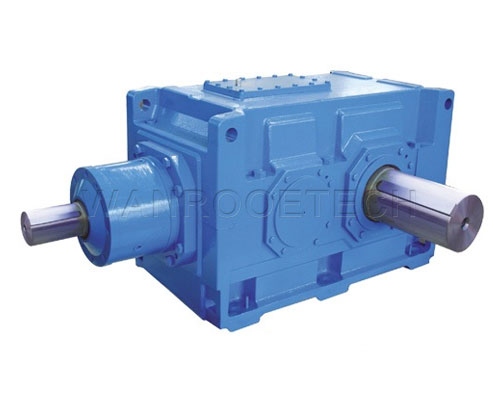

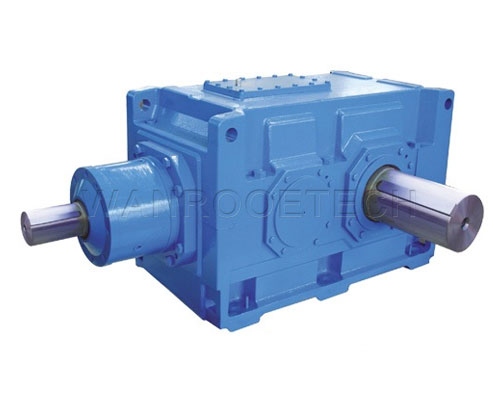

The water generated during the squeezing process is drained from the leaking tank. Due to the particularity of the water quality, the leaking tank is mostly made of stainless steel to prevent rust and corrosion. | Gearbox

Forged by heavy-duty gear material 20CrMnTi carburized steel, by hobbing and grinding gears and other processing technology bearings for thrust bearings, can fully withstand the axial load, wear-resistant smooth and low noise. |

|  |

Motor

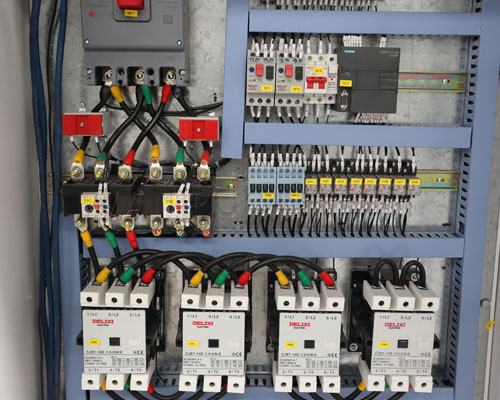

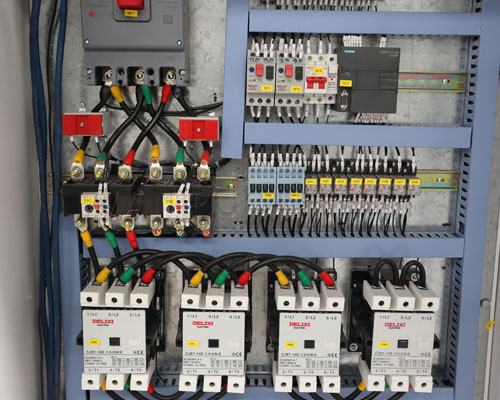

The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Electronic Control

The whole model adopts frequency conversion control and conforms to international standards such as CE/CSA. |

Plastic Film Woven Bag Screw Press Squeezing Dryer Machine Features:

Adopt the latest technology from Taiwan;

Suits for PP/PE film and PP woven bags;

Highly improve quality and productivity of the PP/PE granulating line;

Moisture of the final pellets: <2%

Recycling Process: