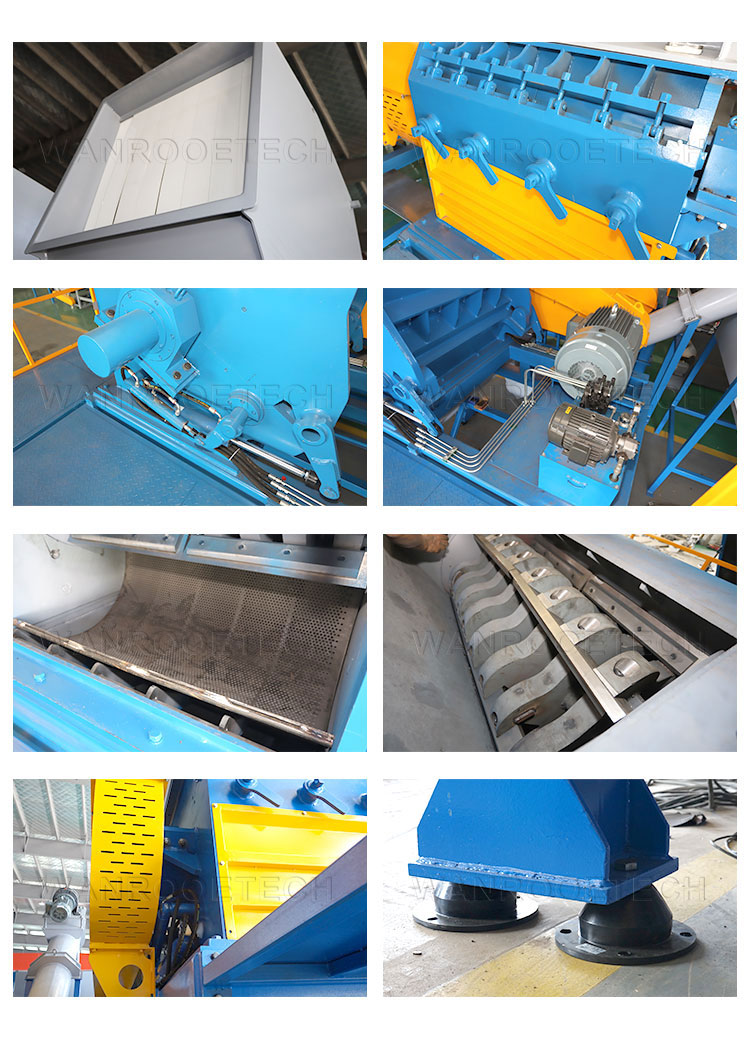

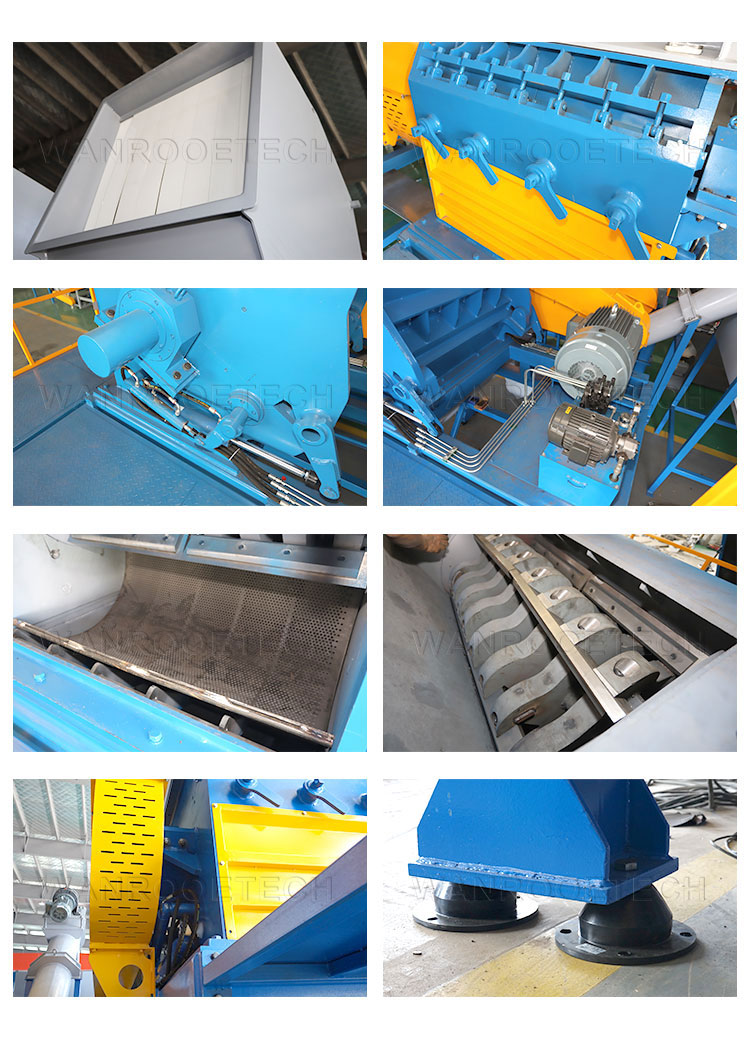

Wet Cursher Machine Description :

An upgraded version of our general purpose wet plastic crusher, these wet plastic crusher machines offer the same speed and efficiency for cutting plastic bottles, films, and rigid with an added twist. We have upgraded the rubber seals and materials to allow for water to be sprayed directly into the cutting chamber. There are major benefits of a wet granulation process that results in long-run savings for your recycling operation.

The most obvious advantage of adding water to your granulation process is it partially cleans and loosens the dirt and contaminants from the recycling stream. This is a great way to pretreat the plastic for further cleaning with our high-speed friction washers.

Water acts as lubrication for the fast spinning blades to reduce friction and heat buildup resulting in improved durability of the blades and machine as a whole. This greatly extends operation times before needing to sharpen the blades.

Due to the dusty nature of plastic recycling streams, a wet plastic crusher process offers the major benefit of lowering dust buildup in your plant.

Wet Cursher Machine Working Principle:

In terms of grinding, our wet plastic crusher machines are identical in structure to our general-purpose plastic crushers. At the core of this machine is an open rotor mounted with ultra-durable D2 (equivalent to SDK11) high-carbon, high-chromium steel knives in either a double-scissor cut or v-shape array based on your requirements.

For purposes of cutting PET bottles and plastic films, we suggest using the v-shape arrangement. If the granulator is mainly used to cut rigid plastics, use the double-scissor cut arrangement.

As the rotor is spun at high speeds between 400-600 rpm, these extremely sharp rotor knives come in contact with stationary knives that are mounted within the cutting chamber.