Plastic Film Woven Bag Double Single Shaft Shredder Application :

PP PE Plastic Film Woven Bag Double Single Shaft Shredder Machine is suited for shopping bags, garment bag, plastic bag, food bag/wrap, bubble wrap, pallet wrap, shrink wrap, paper towel and toilet paper overwrap, air packs (from shipped packages), agricultural film, industrial film, BOPP plastic film, printed film, woven bag, tons bag, jumbo bag, raffia bag, Big Bag, Raffia Big Bag, Bulk Bag, etc.

Plastic Film Woven Bag Double Single Shaft Shredder Description:

Double single shaft shredder machine is a widely used in medium, low speed high torque of crushing equipment.

With the unique design of rotor and cut chamber, the rotor knives and the counter knives cut materials perfectly so that it can not only cut materials evenly but also reduce the dust of the raw materials reasonable.

It can reduce the wear of knives and screen. Rotor shaft surface can be build-up welding wear-resisting layer, making the shredder more suitable for the easily wearing material to have the most abrasion performance and better usage rate.

Double Single Shaft Shredder blade:

Plastic Film Woven Bag Double Single Shaft Shredder Working principle:

Double Single Shaft Shredder use dual-motor to drive dual-gearbox, turn high rotate speed of the electric motors into the low rotate speed of cutter rollers by gearboxes, then cutting, squeezing, and tearing big materials, shred them into small broken pieces.

The rotate speed of the cutter roller is nearly 10-25RPM. The low rotate speed with high torque force. And the materials of cutters are high-quality alloy steel with good abrasion resistance.

Plastic Film Woven Bag Double Single Shaft Shredder Features:

|  |

V-cutting rotor design with staggered cutter positioning | Heat treated rotor knives Special DC53 steel (hardened) four edges use before replacement |

|  |

Twin Rotors Design Twin rotors design, generating tearing and shredding effect; | Wear Resistant Tungsten surface coating for abrasive applications |

|  |

Big-volume hopper For efficient feeding and applicable to be connected with an in-feed conveyor | Replaceable screen at the outlet For controlling shreds under the required size. The size of the screen hole is customizable |

|  |

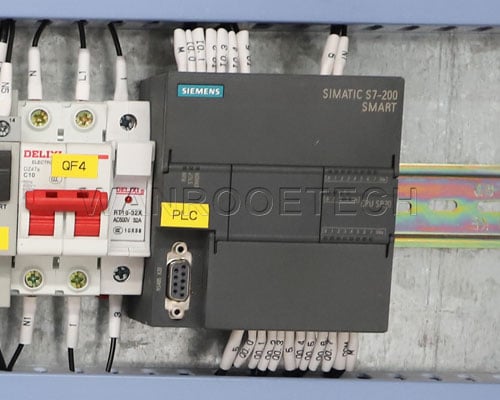

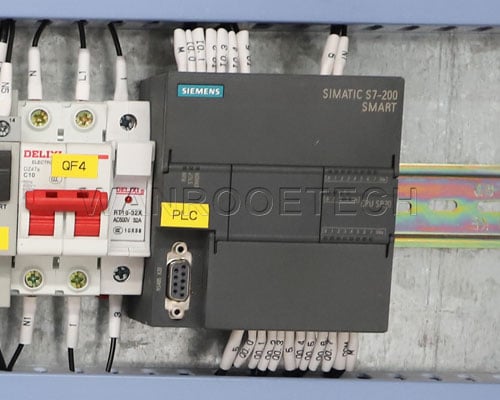

PLC control Making it easier for fault diagnosis and maintenance | Dual motor design For increasing the output |