Single Shaft Plastic Bottle Barrel Drum Bucket Shredder Application Areas:

Single Shaft Plastic Bottle Barrel Drum Bucket Shredder is mainly used to tear plastic buckets, chemical buckets, blue buckets, mineral water bottles, PET bottles, oil bottles, gasoline bottles, plastic buckets, hard plastics, plastic boards, home appliances plastic shells, car plastic hood, hard plastic products. After shredding can be broken by the crusher after plastic pelletizer or plastic crusher, our company can be used for users to customize supporting production line, details can contact us.

Single Shaft Plastic Bottle Barrel Drum Bucket Shredder Description:

Plastic bottle barrel drum bucket shredder is swing arm single shaft shredders, it is heavy duty machines suitable for processing a wide range of materials.

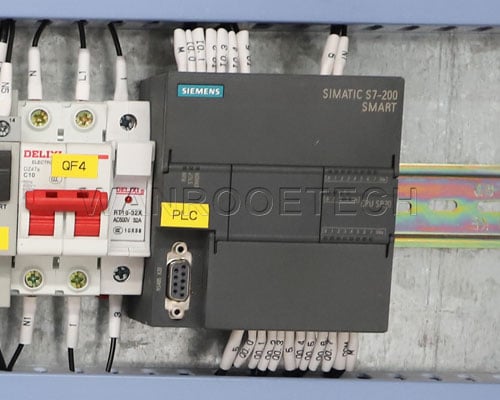

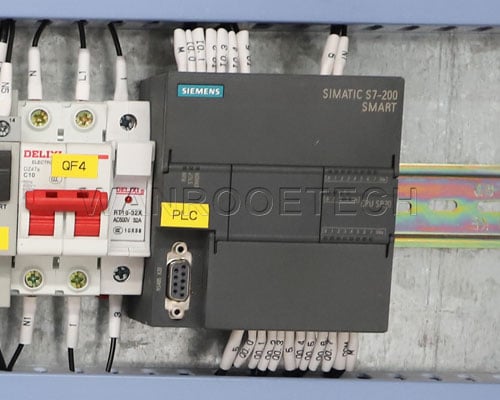

This range of shredders are ideal for the size reduction of flexible and/or medium hardness, volmunous products often loaded in bales. The fast acting, PLC controlled swing pusher automatically forces material to the rotor according to motor loading, maximizing material throughput. Machine capacities typically range between1,500kg/hr –9,000kg/hr+ depending on the model, material type and application.

Single Shaft Plastic Bottle Barrel Drum Bucket Shredder Blade:

Single Shaft Plastic Bottle Barrel Drum Bucket Shredder Components:

|  |

Hydraulic-driven swing pusher To push the objects close to the rotary cutters to achieve efficient shredding performance | Heat treated rotor knives Special DC53 steel (hardened) four edges use before the replacement |

|  |

V-cutting rotor design with staggered cutter positioning | Wear Resistant Tungsten surface coating for abrasive applications |

|  |

Easy operation Simply press the buttons on the control panel to control every movement, and “auto mode” can be selected on the control panel for fully automatic operation | Replaceable screen at the outlet For controlling the output granules below certain size. Size of the screen mesh can be customized according to your need |

|

|

PLC control Making it easier for fault diagnosis and maintenance | Hydraulic System The pressure and rate of flow can be adjusted according to different materials. |

Single Shaft Plastic Bottle Barrel Drum Bucket Shredder Features:

1)Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power slewing axis; Big hopper with big caliber for feeding big material

2)PLC control system with automatic overload protection and auto-reverse switch

3)Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4)Each dynamic blade has four cutting edges which enable reutilization after being abraded, by rotating 90 degree

5)Each fixed blade has two cutting edges which enable reutilization after being abraded, by rotating 180 degree

6)Quiet operation at low speed

7)Screen perforation is adjustable according to customers' requirement

8)The shredders can be adjusted according to customer specific requirements for throughput volume, material to be processed, etc.