Wheat Corn Cotton Stalk Straw Shredder

Views: 6691

Author: Site Editor

Publish Time: 2020-11-19

Origin: Site

Description:

It is understood that for the treatment of straw, some farmers used to transport it home and burn it for cooking, and some of it was burned directly in the field. Nowadays, with the improvement of living standards, most farmers no longer use rice straws for cooking in their homes. On the other hand, the state is paying more and more attention to environmental protection, and the supervision of rural straw burning has become more stringent. A difficult problem.

Before the straw shredder

Now the crops are basically mechanized planting, and the harvest is also crushed and bundled, which makes it convenient for us to transport and store. Although baling is convenient for transportation and storage, it is very inconvenient in terms of biomass combustion and reuse. Because the volume of baled straw becomes larger and it is difficult to process, we need this straw stalk crusher for crushing processing. , The fineness of crushed materials is satisfied with the reuse of multiple industries. For example: In addition to making daily necessities and industrial supplies, it can also be developed into biomass fuels.

Straw shredder is mainly composed of the main shaft, blade, middle comb plate, box body, power system, etc. Using low-speed, high-torque dual motors to directly drive the knife roller. Use the interaction between the movable knife and the middle comb plate to cut, tear, and pull the material to process the material. It has the characteristics of large crushing force, high output, low noise, and good stability, and is often used for the crushing of crop straw for biomass power generation.

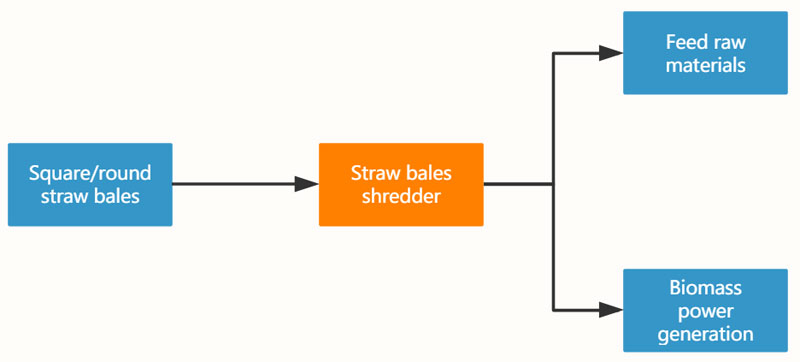

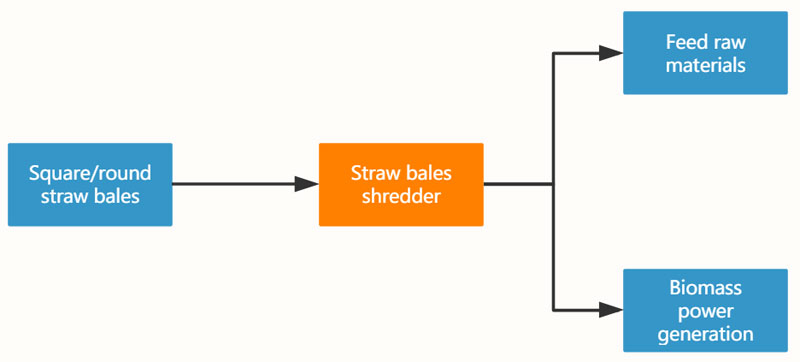

Process flow chart of straw bale shredder

Working principle of straw bale shredder process flow chart:

Straw shredder uses low-speed, high-torque dual motors to directly drive two knife rollers, and uses the principle of mutual shear and tearing between two relatively rotating knives on the knife roller to crush materials, which is very good for soft and hard materials. Good crushing effect; good running stability, low noise and high degree of automation. Compared with traditional double-shaft crusher equipment, this equipment has the advantages of lower noise, stable performance and energy saving.

Features of straw bale shredder:

This device adopts low-speed, high torque dual motor direct drive, with high transmission efficiency, low energy consumption, and stable crushing. The fixed knife is independently detachable, making it easy to replace quickly and reducing maintenance time and costs. The spindle is made of high-strength alloy steel, which undergoes heat treatment and high-precision processing to ensure long-term use without deformation and impact resistance. The discharge particle size can be adjusted to meet different needs. Low noise and minimal dust during operation, with superior environmental performance. Widely applicable, not limited to straw bales, but can also handle biomass materials such as tree branches and wood. Overall, the straw baler shredder has the characteristics of high efficiency, flexibility, durability, environmental friendliness, and wide applicability, making it an ideal choice for agricultural waste treatment.

In order to better provide you with a professional answer, when sending an inquiry, please describe your parameters or technical requirements (such as processing materials, output size, capacity, etc.), we will reply to you as soon as possible!