Paper Pulp Recycling Drying And Baling Plant

Paper pulp recycling drying and baling plant is a system that includes separation, dewatering and baling. PLC intelligent system achieves a high degree of automation and the whole line requires only 2-3 people to operate. With more than 20 years of recycling experience, WANROOE has not only mastered the key technologies but also improved the machine design for specific products. wanrooe provides fiber pulp recycling solutions with high output and low energy consumption.

What is paper pulp?

Fibrous paper pulp is usually the waste from the paper mill's upstream production process and usually contains 90% paper fibers, 9% plastics and 1% other, which contains 70% water and 20% metal wires. Currently, paper pulp is sent to landfills, but this pulp stock can be recycled as long as the plastic and metal are separated.

Why do we need to recycling paper pulp?

Depending on the paper mill process, scrap paper makes up about 5-25% of the paper. These waste products include materials such as plastics, metals and fibers that are separated from the wet pulp. Due to its high calorific value but high moisture content, one of the main challenges in this part is how to optimize the drying process. Moisture adds weight and creates unnecessary costs in terms of transportation and gate fees. In addition, more moisture means less continuous incineration, requiring additional heating. wanrooe optimizes the drying process for these solids, eliminating the need for multiple drying steps in the pulp stock recovery process.

By drying and baling the pulp, the weight and volume can be effectively reduced, significantly reducing transportation costs, setting the stage for subsequent recycling, reusing the resource, and creating commercial value.

How to recycle paper pulp?

The alternative fuel preparation system for paper mills is developed for the characteristics of pulp materials. The solution mainly adopts extrusion dryer and horizontal baler as the core equipment, and the control program is set according to different material properties, and the materials are conveyed, broken up, iron removal, sieving, extrusion dryer and baling, so that the metals, other mixtures and combustibles in the materials are fully separated, and the metal melting can be reused, and the plastics can be used for re The pulp is used as a raw material for recycled paper; the resource is recycled and the combustible material is used as "alternative fuel (SRF)" to reduce the use of coal. Value is created and the environment is protected.

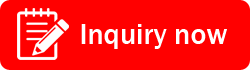

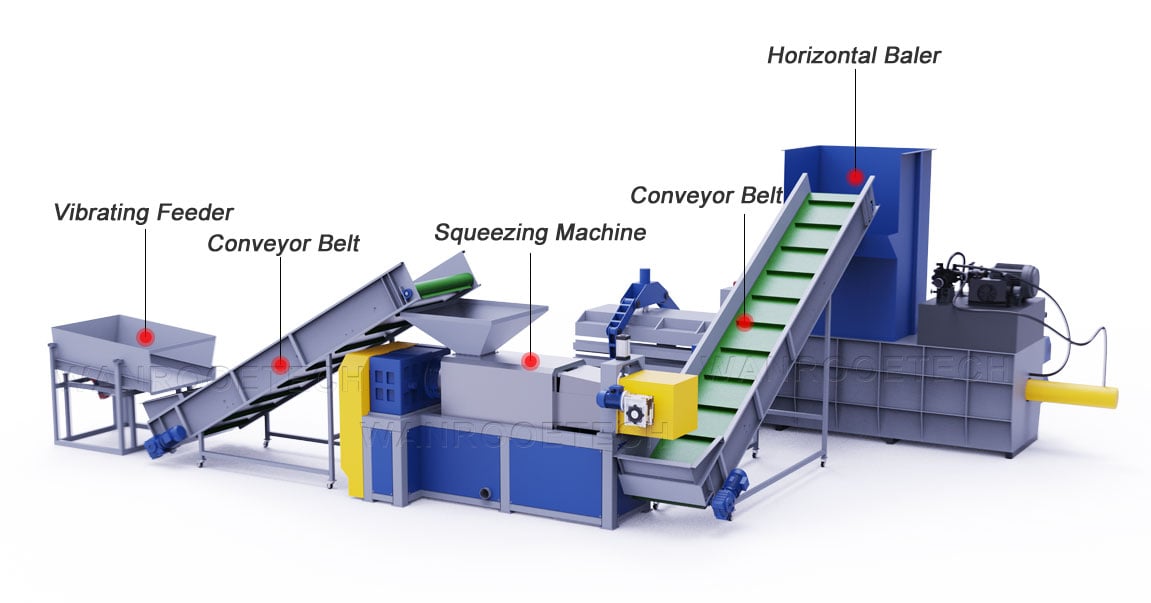

Paper Pulp Recycling Process:

Vibrating feeder + conveyor belt + suspended magnetic separator (to remove the iron wire inside the pulp material) + magnetic roller (to remove the iron wire inside the pulp material) + squeezing dryer (to remove the moisture inside the pulp material) + conveyor belt + horizontal baler

Paper Pulp Recycling Main equipment.

|  |

Vibrating feeder:

scattering pulp waste evenly, regularly and continuously by vibration, which is convenient to separate the metal of pulp material. | Conveyor belt:

conveying the paper pulp material to the squeezing and drying machine. |

|  |

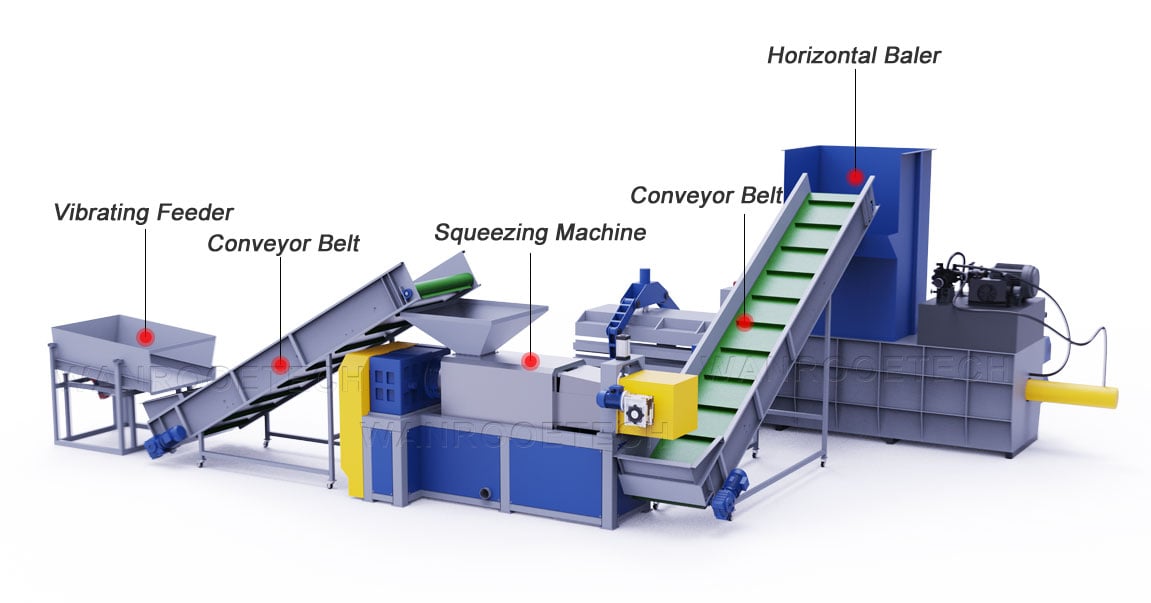

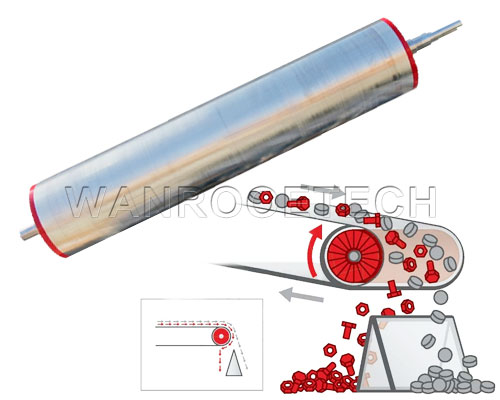

Suspended magnetic separator:

for removing the iron wire inside the pulp material and separating the iron wire out. | Magnetic roller separator:

to further remove the iron wire inside the paper pulp. |

|  |

Squeezing machine:

remove the water inside the pulp material by spiral squeezing. | Horizontal baler:

compress the pulp material into square dense bales and bundle them with steel wire for easy transportation and storage. |

Paper Pulp Recycling Dewatering And Baling Line Advantage

Labor saving, full automation, only 2-3 persons are needed for the whole process.

Effective separation of metals: Through suspended magnetic separator and combined with magnetic roller separator, the removal rate of magnetic metal reaches 99.7%.

Weight reduction: effective weight reduction of 40-50% by squeezing dryer, saving transportation costs.

Reduction of volume: effective reduction of volume through horizontal baler, reducing transportation costs.

In order to better provide you with a professional answer, when sending an inquiry, please describe your parameters or technical requirements (such as processing materials, output size, capacity, etc.), we will reply to you as soon as possible!