Double Shaft Shredder Machine Description:

Double shaft shredder is appropriate for waste materials recycling requirements of various industries, such as electronic waste, plastic, metal, wood, scrap rubber, packing barrel, layer board and so on. There is a wide range of recyclable materials, and materials after shredding can directly be reused or for further refining treatment according to requirements. This double shaft shredding machine has the characteristic of slow speed of revolution, high pulling torque and low noise, etc. Adopting PLC(Programmable Logic Controller) control system, it can automatically control the start and stop function, reversal function, and automated inversion of control function when overloading of this twin shaft shredder, which greatly lowers labor and meanwhile generates high efficiency.

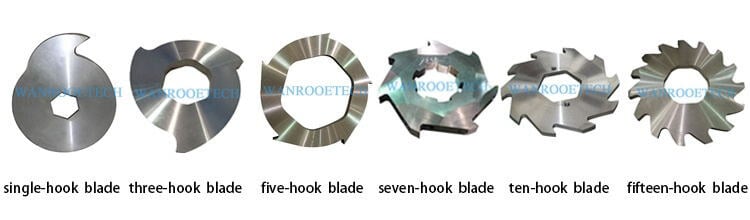

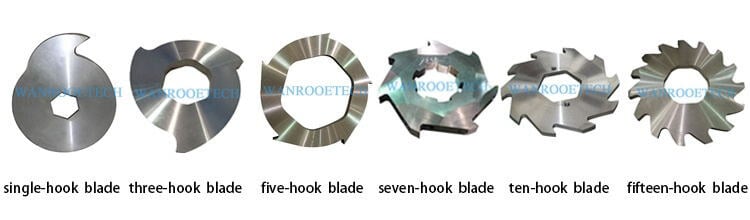

Double Shaft Shredder Blades(According to different materials choose different blades ):

Double Shaft Shredder Machine Components:

|

|

Shredder Chassis The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

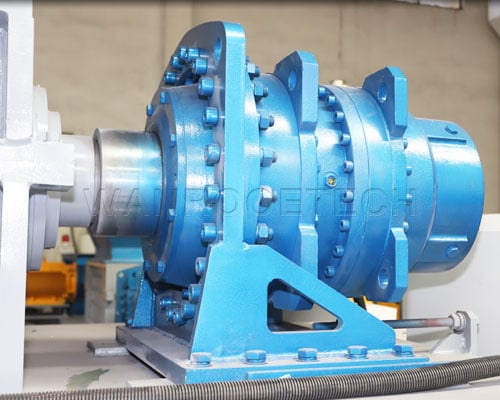

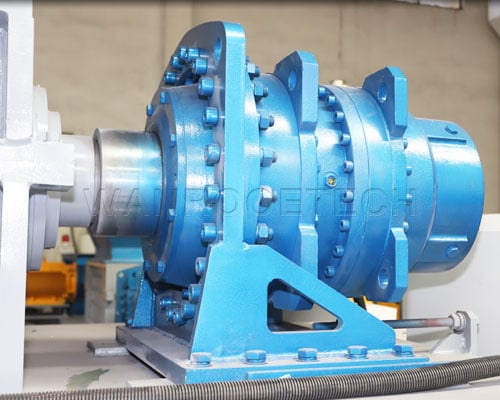

Hydraulic Force Feeder(optional) A hydraulic force feeder is available to actively press the input material down into the cutting zone between the two shearing shafts. This holding action prevents material from riding over the blade hooks, thus greatly improving the cutting efficiency and throughput of the machine. | Planetary Reducer The reducer chassis adopts welded box, helical gear, planetary gear transmission, with small volume, low noise, high torque and other characteristics, higher transmission efficiency. |

|  |

Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Rotary Screen(optional) To effectively control the output product size, a circular screen mounted around the cutting chamber is the ideal solution.The rotary screen runs at low speed, the oversized fractions are recirculated back to the cutting chamber for further shredding, whilst the sized fraction falls through the screen to the next process. |

![]()

Double Shaft Shredder Machine Technical Features:

The technical characteristics of the double shaft shredder are significant: the main body is welded with high-quality steel plates, the structure is stable, and it can operate stably under heavy loads for a long time; The shaft seat adopts a patented detachable design, which facilitates the quick disassembly of moving and fixed blades and other components, with efficient maintenance and low cost; The moving knife is made of special alloy tool steel through precision forging and multiple heat treatments, with strong wear resistance and toughness, and can be repaired repeatedly. The fixed knife has a patented hook installation and optimized tool replacement; The blade shaft is refined with high-strength heavy-duty steel, closely matched with the cutting tool, and has strong cutting power; Compared to single shaft shredders, its double shaft design generates strong shear and tearing forces, making it easy to crush large-sized materials such as wooden boards and tires. It is widely used in fields such as waste recycling and garbage disposal.

Double Shaft Shredder Machine Application Areas:

Due to its versatility, this series of double-shaft shredders can be commissioned in a multitude of industries including but not limited to:

Rubber Recycling: rubber sheet, rubber pad, car tires, heavy truck tire

Metal recycling: steel drum, steel sheet, steel cans, aluminum cans, aluminum rods, etc.

E-waste (electronics waste) or WEEE recycling

Wood Recycling: lumber, wooden pallets, furniture, tree branches, wooden frame, etc.

Destruction of products for liability issues such as sensitive documents including computer storage media such as hard disks, x-rays, expired goods, outdated stock, pharmaceuticals, etc.

Size reduction in wastewater treatment plants and other municipal applications.

Pre-cutting other solids such as destruction of foods, pallets, steel and plastic drums, furniture, construction debris, containers, corrugated boxes, packaging, labels, and other bulky materials.