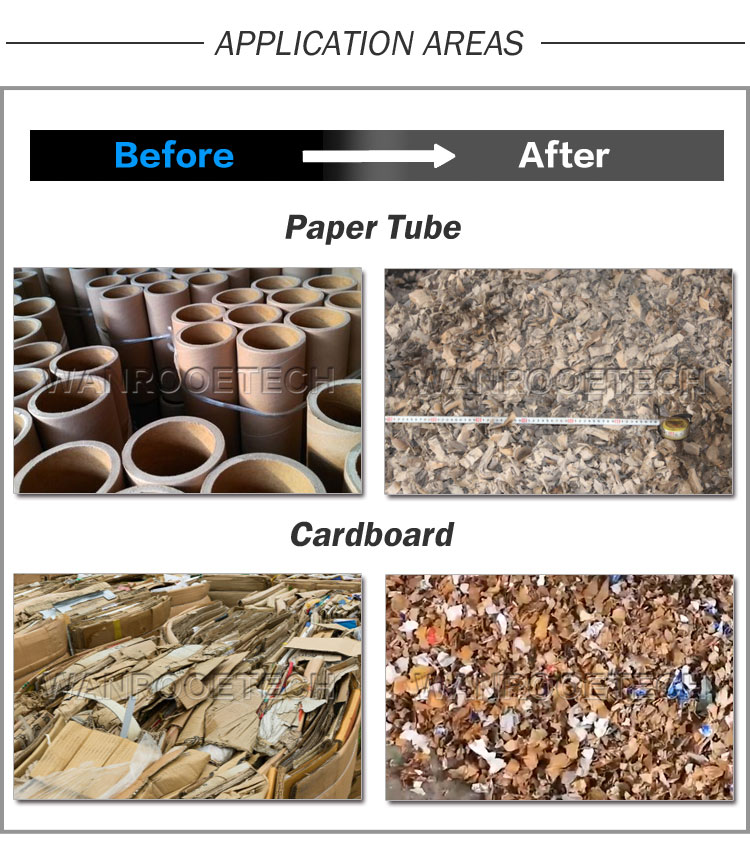

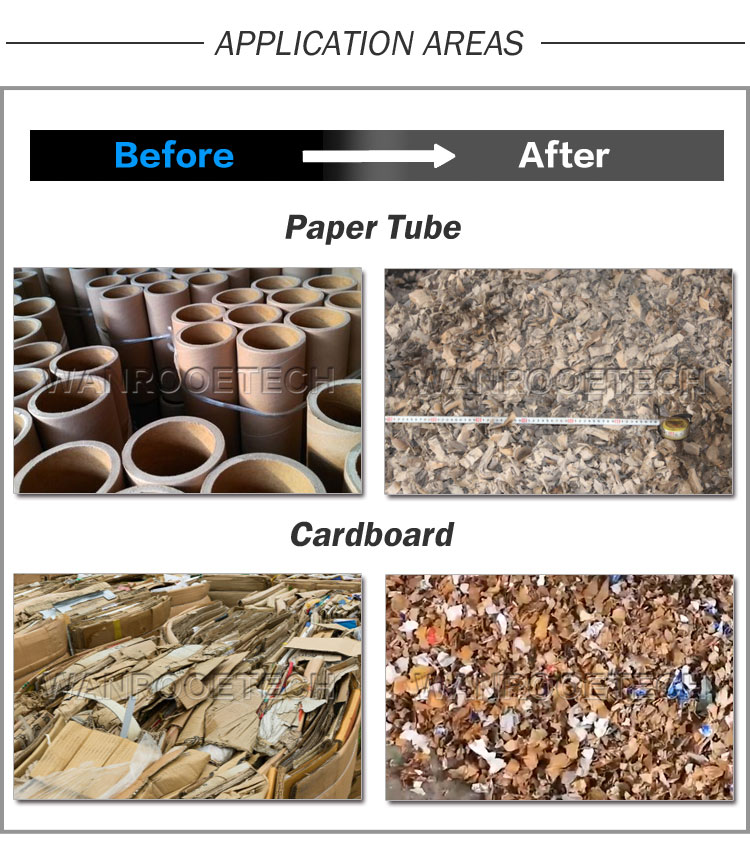

Paperboard Books Magazine Cardboard Newspaper Shredder Application Areas:

Paperboard Books Magazine Cardboard Newspaper Shredder is suitable for shredding waste corrugated paper, paper, hard paper, newspapers, office paper, magazines, books, cartoons, kraft paper, paper core, paper tubes, cardboard, paper packaging material, and other paper materials.

Paperboard Books Magazine Cardboard Newspaper Shredder Description:

Double Shaft Shredder with loading hoppers, equipped with high-quality cutters with low rotation speed for lower energy consumption and noise reduction. It incorporates two counter-rotating shafts that intermesh with each other(2 shafts with sharp elements constituted by sharp-corners disks provided with hooks; Every hook has the task to hook the product and drive-it by the action of the two counter-rotating shafts). The material is powerfully torn and shredded by the talons of the cuttings discs. Specially designed rotor makes the shredder be extremely worn resistant.

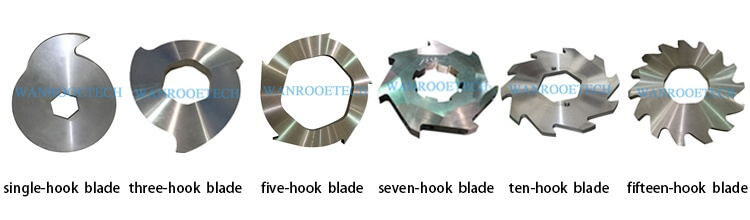

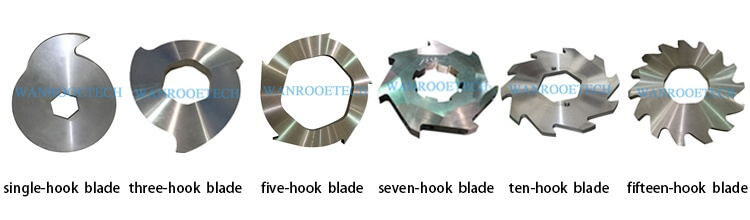

Double Shaft Shredder Blades(According to different materials choose different blades ):

Paperboard Books Magazine Cardboard Newspaper Shredder Components:

|

|

Shredder Chassis The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

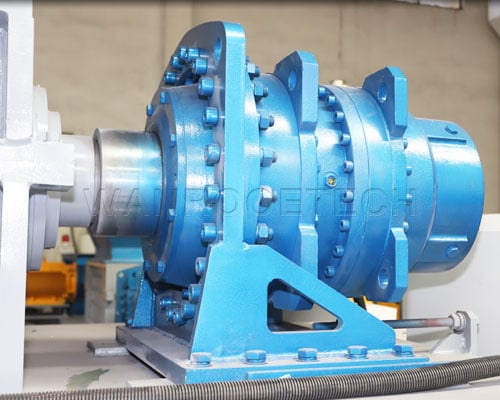

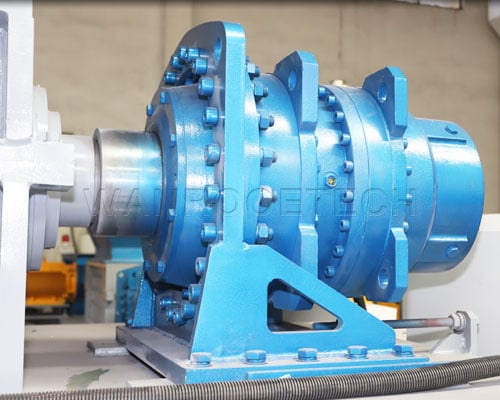

Hydraulic Force Feeder(optional) A hydraulic force feeder is available to actively press the input material down into the cutting zone between the two shearing shafts. This holding action prevents material from riding over the blade hooks, thus greatly improving the cutting efficiency and throughput of the machine. | Planetary Reducer The reducer chassis adopts welded box, helical gear, planetary gear transmission, with small volume, low noise, high torque and other characteristics, higher transmission efficiency. |

|  |

Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Rotary Screen(optional) To effectively control the output product size, a circular screen mounted around the cutting chamber is the ideal solution.The rotary screen runs at low speed, the oversized fractions are recirculated back to the cutting chamber for further shredding, whilst the sized fraction falls through the screen to the next process. |

Technical Features:

An industrial cardboard shredder on an industrial and commercial scale can process cardboard waste and paper products in a large quantity.

A heavy-duty cardboard shredder can work with a dust collection vacuum.

A cardboard or paper shredder enables you to dispose of this real quick.

Recycle cardboard more efficiently.

Safely destroy voluminous waste and confidential documents.

Save your valuable time to do the shredding, and the shredder machine is easy to operate and manage.