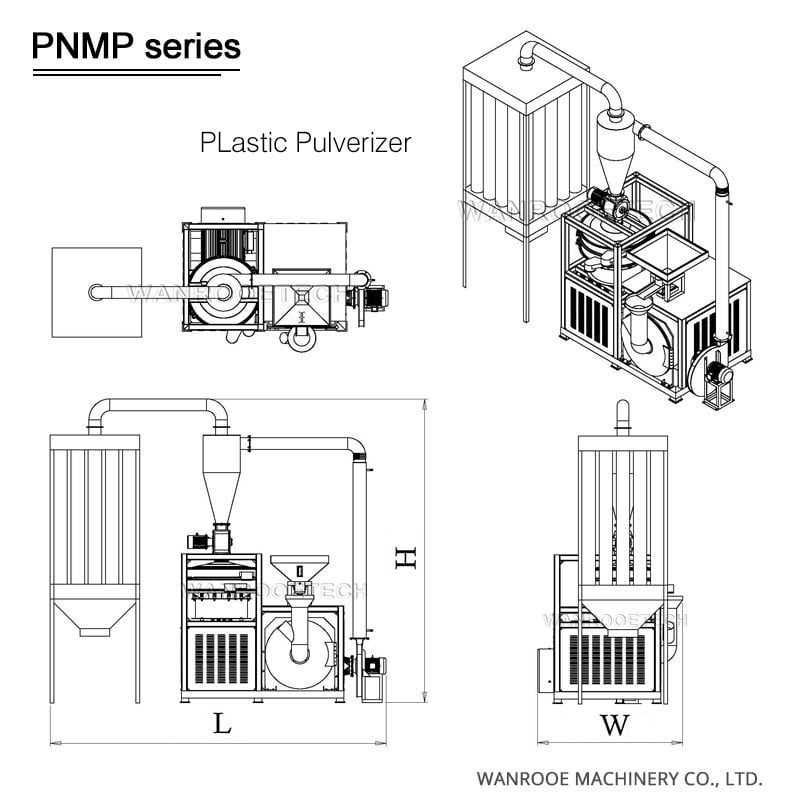

Fiberglass Reinforced Plastic FRP Pulverizer Mill Machine Description:

PNMP fiberglass plastic pulverizer mill is chiefly designed to grind PVC. The pulverizer uses turbo type blade. The static blade and rotary blade could be adjusted, thus you can get different sizes of PVC powder with one grinder. High output, low energy consumption and long lifespan attract many customers around the world. It can be used for PVC plastic from PVC pipe/profile/soft sheet/bottle/card from low to moderate hardness PVC.

The output of our PNMP pulverizer can reach 100-900kg/h (15-100mesh).

The plastic pulverizer machine is mainly composed of an electric motor, disc-type blade, feeding fan, vibrating sieve, dust removing system, etc.

According to the customer's needs, you can choose some accessories, such as converter, vacuum loader, screw loader, magnetic net, metal separator, chiller, pulse dust collector, metering and weighing packaging machine, etc.

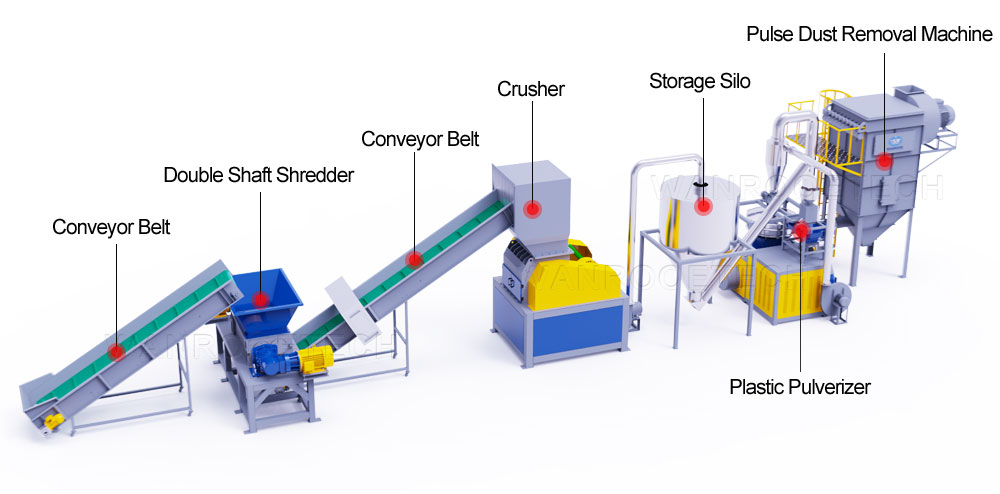

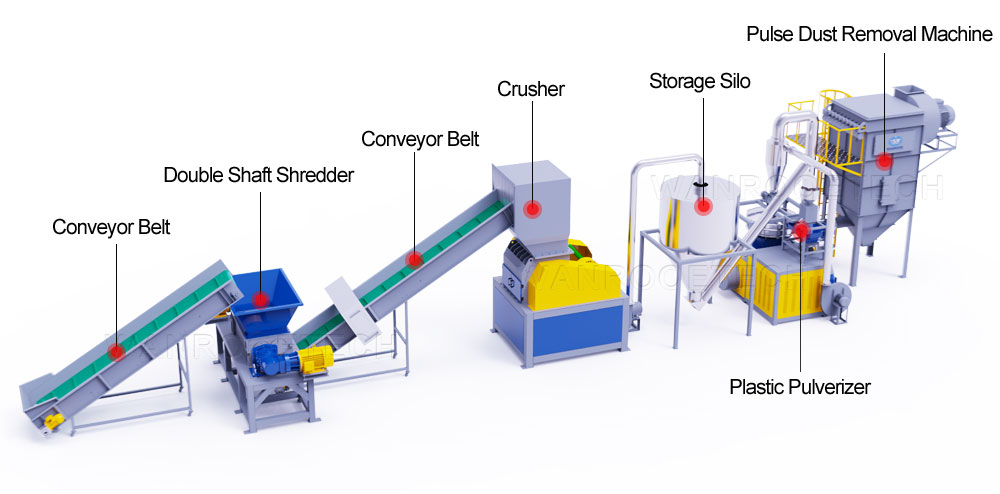

Fiberglass recycling process:

Waste glass fibers are first fed into a shredder through an input belt for shredding. After shredding, 30-50mm glass fiber material can be obtained, and the specific size can be controlled by the shredder screen. At the same time, the output size can also be adjusted by the conveyor belt. Subsequently, these glass fiber materials enter the plastic crusher and are further crushed to a particle size of 3-8mm. The crusher screen can control the discharge particle size. Next, the crushed glass fiber material enters a plastic mill for grinding, and a vibrating screen is used to control the particle size of the grinding mesh. Due to the high content of calcium carbonate in fiberglass, pulse dust collectors are also required in the process to remove dust and purify the air.

Step 1: Fiberglass shredder

Fiberglass shredder is a double shaft shredder machine, that is used to shred fiberglass into small pieces. Fiberglass recycling we recommend that you choose a twin shaft shredder, we have tested, if you use a single shaft shredder, the single-shaft shredder blade damage is relatively large, while the twin-shaft shredder is the perfect solution to this problem. There are many types of fiberglass shredders with different capacities and output sizes. You can always find the most optimal fiberglass shredder according to your actual needs. Fiberglass shredder is widely used in fiberglass recycling. This shredder machine can make the fiberglass easily re-used in the following process.

Step 2: Fiberglass crusher

Fiberglass crusher machine is a kind of plastic crusher machine used for crushing waste fiberglass material with large hardness and tenacity. It is improved and extended on the basis of traditional crusher. Wind motor is arranged for the transport of broken material, and a start-up device is arranged. The operation and maintenance & repair are rather simple. It is an ideal model for crushing all sorts of fiberglass material and profiled material.

Step 3: Fiberglass pulverizer

Fiberglass pulverizer adopts a rotor blade design to pulverize waste fiberglass material into power for recycling. It is widely used for recycling waste fiberglass and so on. We have focused on plastic recycling for 20 years. We provide a complete recycling program for fiberglass waste. If you have any needs, please contact us.

Step 4: Pulse Dust Catcher

Because the waste fiberglass recycling process generates a lot of dust, we recommend using pulse jet bag dust collector, to protect the health of the staff and keep the factory clean at the same time. It applies to the treatment of high concentration dust, overcomes the disadvantages of bad dust cleaning, air leakages, improper design, and simplifies the process of dust control and reduces equipment investment.