Woven Bag Shredder Applications:

Medical waste: surgical gowns, melt-blown nonwovens.

Post-consumer waste: Air-laid paper, resin bag.

Geotextile: sandbags, Disposable towels, woven bags, non-woven bags, big bags, bulk bags, bulka bags, tonne bag.

PP Woven Bag Shredder Description:

PP bag, woven bag, PP bag, bulk bag and big bag are referring to the same object. All of which is easy to recycle by a woven bag Shredder (Woven Sack Shredder). A shredder for big bags can usually handle bags in bales. This allows fast shredding and whole bale feeding. Also, this machine can process with an outputt around 500kg/hr to 2000kg/hr.

If woven bags come in bales, we need a pre-shredder or manually debaling. Our shredders can be fed by conveyor belt, forklift or manually and are optionally equipped with mechanical or hydraulic drive. It is common to implement a single shaft shredder or a double rotor shredder.

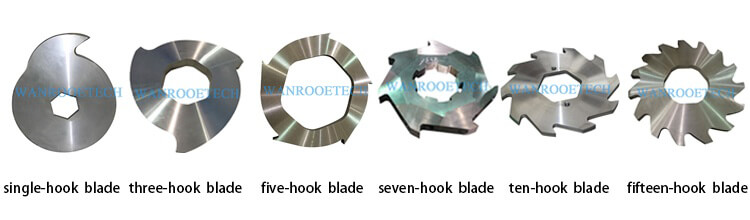

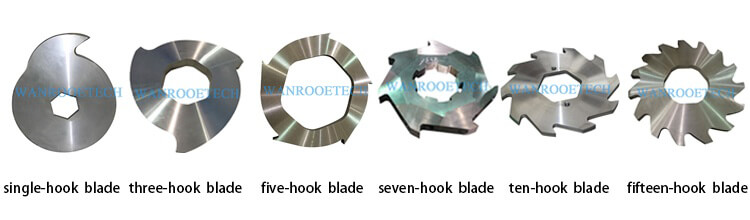

Double Shaft Shredder Blades (According to different materials choose different blades ):

Woven bag shredder in scrap woven bag recycling

Recycling and re-use of plastic woven bags contribute to economic prosperity and continuity through cost savings on raw material and resource conservation. Size reduction is an important step in woven bag’s recycling process. The collected waste woven bags are shredded or granulated into small pieces and then further get washed, separated and dried. At last, the cleaned pieces are melted down and made into new products.

PP Woven Bag Shredder Components:

|

|

Shredder Chassis The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

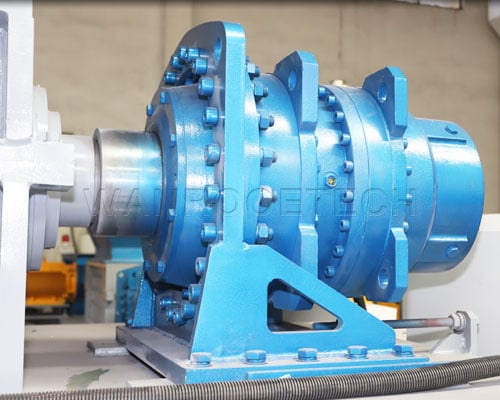

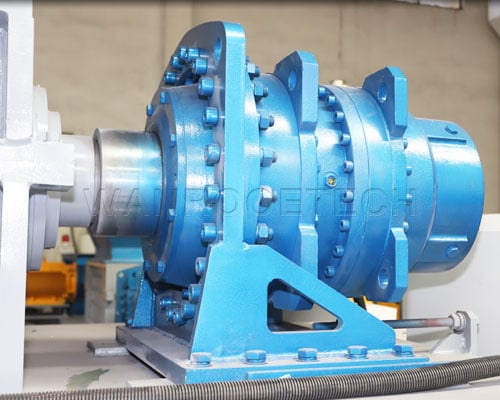

Hydraulic Force Feeder(optional) A hydraulic force feeder is available to actively press the input material down into the cutting zone between the two shearing shafts. This holding action prevents material from riding over the blade hooks, thus greatly improving the cutting efficiency and throughput of the machine. | Planetary Reducer The reducer chassis adopts welded box, helical gear, planetary gear transmission, with small volume, low noise, high torque and other characteristics, higher transmission efficiency. |

|  |

Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Rotary Screen(optional) To effectively control the output product size, a circular screen mounted around the cutting chamber is the ideal solution.The rotary screen runs at low speed, the oversized fractions are recirculated back to the cutting chamber for further shredding, whilst the sized fraction falls through the screen to the next process. |

Woven Bag Shredder Machine Advantages:

The main body of the double axis shredder is welded with high-quality steel plates, laying a solid foundation for the stability of the equipment during long-term heavy load operation; The shaft seat adopts a patented detachable design, which can conveniently and quickly disassemble components such as moving blades and fixed blades, making it easy to maintain and replace blades; The moving knife is made of special alloy tool steel, which has undergone precision forging, multiple heat treatments, and low-temperature freezing treatments, making it reusable and repairable. The fixed knife adopts a patented hook installation, optimizing the tool changing process; The blade shaft is refined from high-strength, heavy-duty specialized steel, and is well matched with the cutting tool to provide strong power for cutting. In addition, compared to single axis shredders, double axis shredders can easily crush large-sized materials such as woven bags, wooden boards, wood, tires, etc.