PET Washing Line Description:

The PET bottle recycling plant takes dirty bottles and transforms them into clean PET flakes. And the flakes can be further processed and reutilized with high commercial value. The production capacity we can make on the PET Bottle washing and recycling line can be 300kg/h to 3000kg/h. The line's main purpose is to intend to get clean flakes from the dirty even mixture bottles or bottles slice during dealing with the whole washing line. And also get a clean PP/PE collection, labels and paper chips, etc.

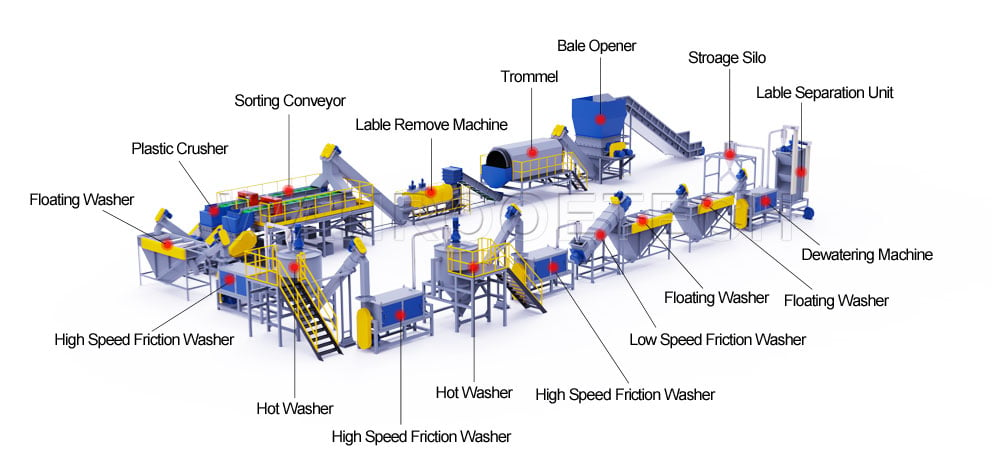

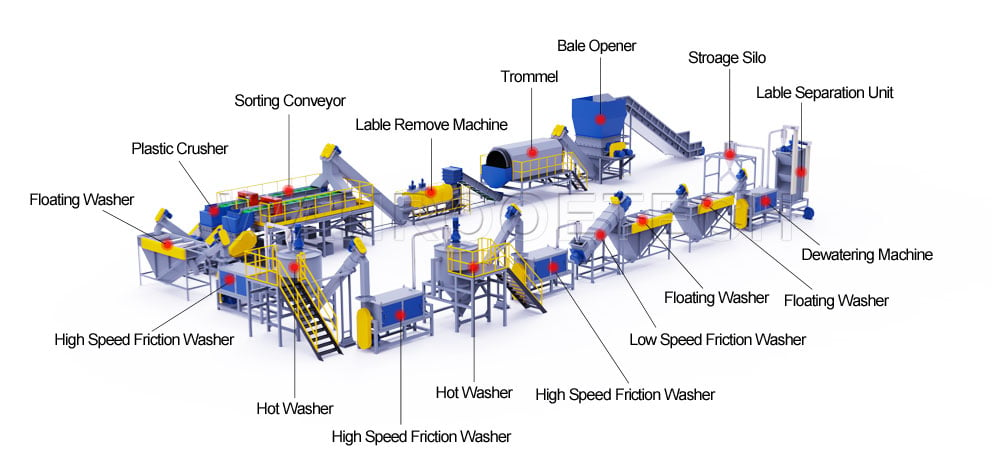

The device is divided into unpacking, washing, sorting, detecting metal, crushing, floating washing, hot washing, rubbing, rinsing, dehydration, drying and packaging process steps.

PET Washing Line Process Flow:

NO | Process | Machine | Description |

1 | Break the compacted bales(Optional) | Bale Opener | As PET bottles generally arrive at washing plants in bales, or compacted bundles of plastic bottles, they must first be unpacked before the bottles can flow freely onto the belt conveyor system. |

2 | Primary separation of sand and gravel | Trommel | Remove small contaminants such as broken glass, paper/cardboard, metals, rocks. |

3 | Remove the label | Label Remove machine | Remove the label from the bottles. |

4 | Sort out different color bottles, and labels | Sorting Conveyor | Picking out the different color bottles and also the bottle still have the label, which makes sure the end products of PET flakes same color and much more clean. Metal Detector is optional. |

5 | Crushing PET Bottles into PET Flakes | Wet Crusher | Using a wet crusher, whole PET bottles are cut into PET flakes between 12-18mm in size. |

6 | The First Time Floating washing the PET flakes | Floating Washer | A way to separate materials that float from those that sink, the sink/float separation tank is ideal for PET recycling as PET flakes sink while plastic film, PP/PE bottle caps, and other contaminants float. |

7 | Break down the oil & glue | Hot Washer | Using the hot water and chemical to break down the oil and glue on the PET bottles. |

8 | Separating the contamination | High Speed Friction Washer | The friction wash uses high speeds to create friction between the PET flakes where debris is effectively scrubbed off. |

9 | The Second Time Floating washing the PET flakes | Floating Washer | It is used in cleaning pet flakes, making the flakes cleaner and whiter. |

10 | Dry the PET flakes | Dewatering Machine | The dewatering machine uses centrifugal force to spin water moisture off the PET flakes. |

11 | Hot air to dry the PET flakes | Pipeline Dryer | Using the hot air to take the humidity away from the clean material. |

PET Washing Line Components:

PET Washing Line Technical Features:

1. High automation level, try best to reduce your cost on labor (especially for three shifts) and ensure high processing capacity: 100-2000kg/hr.

2. Friendly control system (PLC integrated & separated control on each machine) and Touch screen panel, easy for operation, monitor and emergency stop.

3. All parts contacting with plastic material and water are made of high-quality 304 stainless steel; Ensure no second pollution to flakes.

4. This China Hot Selling Waste PET Bottle Washing Machine can easily wash and recycle waste PET bottle flakes. Equipment at the end of the washing line so that the completely dry flakes can be collected and packed directly after being washed.

5. The whole production line can be designed on the basis of how dirty the flakes are, and make sure of the quality of the final products.

6. Coordinating the production line with follow programmed work (granulating system), and it will make waste and dirty PET bottles be the PET granule material and in order to produce new PET bottles.

PET Washing Line Application Areas:

Bottles jars and other containers made of PET can be collected and recycled into a wealth of products. PET can be recycled into new PET bottles and containers, carpet and clothing, industrial strapping, rope, upholstery fabrics, boat sails, automotive parts, fiberfill for winter jackets and sleeping bags, construction materials, and many other items.