Plastic Pallet Shredder Waste Plastic Tray Shredder Machine Description:

Plastic trays can be used to store, load, and carry their goods, which is one of the indispensable logistics equipment in modern logistics warehousing. The emergence of plastic trays is to adapt to environmental protection. It is the product that is destroyed by forests using plastic trays. It is the product of the development of the forest. With the continuous strengthening of the food safety concept, the plastic tray takes its anti-corrosion, moisture, and prevents Corrodes, insect resistance, unmimerate, etc. are favored and sought after by the food, pharmaceutical industry. In addition, the carrier tray has a high load performance and long service life and has a wide range of applications in chemical, textile, manufacturing and other fields.

Plastic Pallet Shredder Waste Plastic Tray Shredder Machine Description:

Plastic pallet shredders are heavy duty size reduction machines suitable for processing a wide variety of materials including plastic, paper, cardboard, wood, textile, etc. Different from traditional single shaft shredder which is equipped with a horizontal hydraulic pusher, this swing arm type single rotor shredder adopts a hydraulic-driven swing pusher which automatically forces material towards the cutting rotor for achieving the most efficient size reduction performance.

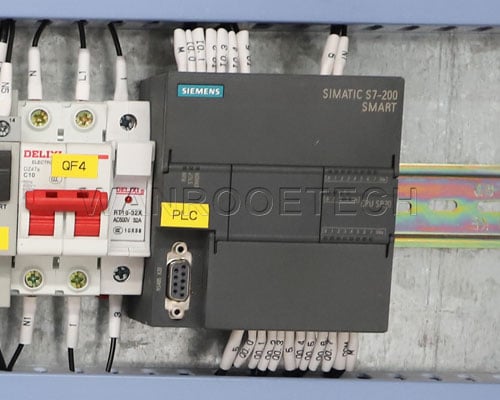

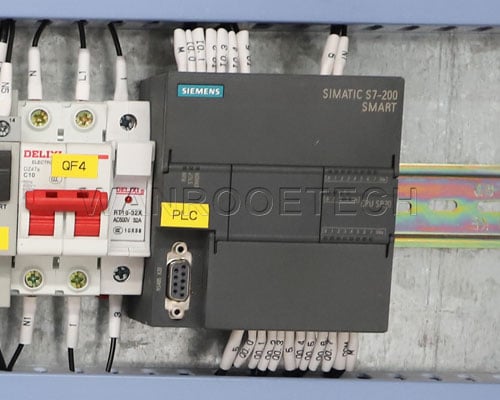

A replaceable screen is mounted underneath the cutting rotor for controlling the shredded material below the screen mesh size. The rotary cutter features with auto reverse function which kicks in anytime in case of some stubborn material or excessive quantities of material that cannot be shredded. This automatic reverse function not only protects machine itself from overloading and breaking, but also guarantees a continuous and streamlined shredding operation. Controlled by PLC system, operation of this single rotor shredding machine is straight-forward, simply press buttons on control panel to control every movement. And “auto mode” can be available for automatic operation to increase working efficiency and meanwhile save labor.

Plastic Pallet Shredder Waste Plastic Tray Shredder Machine Components:

|  |

Hydraulic-driven swing pusher To push the objects close to the rotary cutters to achieve efficient shredding performance | Heat treated rotor knives Special DC53 steel (hardened) four edges use before the replacement |

|  |

V-cutting rotor design with staggered cutter positioning | Wear Resistant Tungsten surface coating for abrasive applications |

|  |

Easy operation Simply press the buttons on the control panel to control every movement, and "auto mode" can be selected on the control panel for fully automatic operation | Replaceable screen at the outlet For controlling the output granules below certain size. Size of the screen mesh can be customized according to your need |

|

|

PLC control Making it easier for fault diagnosis and maintenance | Hydraulic System The pressure and rate of flow can be adjusted according to different materials. |

Plastic Pallet Shredder Waste Plastic Tray Shredder Machine Features:

Energy Efficient + Maximum Cutting Force & Productivity

Shock Absorbing Gearbox reduces Stress on Drive Components

Rotor Knives can be rotated and used on several edges before replacement.

Long Life Counter Knives can be used on two edges and adjusted to maintain cutter clearance

Quick Change Screens for accurate particle size control

Swing Ram Pusher with exchangeable PU Slides

Quick access to the rotor via the rear chamber access door

Twin Speed Hydraulics with integrated air cooler

Stand Alone Electrical Control Panel with Siemens PLC Control System

Tested, Approved and Certified to the applicable CE safety standards