Car Truck Mobile Tire Shredder Machine Waste Tire Tyre Recycling Machine Description:

The car and truck mobile tire crusher and waste tire recycling machine are designed for efficient recycling, capable of producing 1.2 to 10 tons of tire derived fuel (TDF) per hour and producing rubber fragments ranging from 25 millimeters to 152 millimeters as coal additives for industrial boilers. TDF is hotter, cleaner, and more cost-effective than coal combustion. The device consists of two main parts: a dual axis crusher and a screen, which can directly output coarse crushed materials or further process and remove steel wires to generate wireless TDF. Its mobile design facilitates flexible transfer, meets the demand for large-scale waste tire recycling, and provides an efficient and environmentally friendly energy alternative solution for industry.

Car Truck Mobile Tire Shredder Machine Waste Tire Tyre Recycling Machine Components:

|

|

Shredder Chassis The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

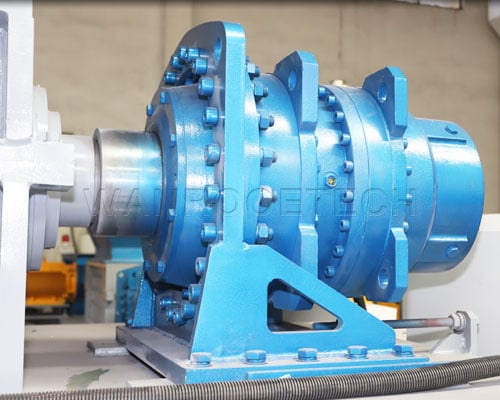

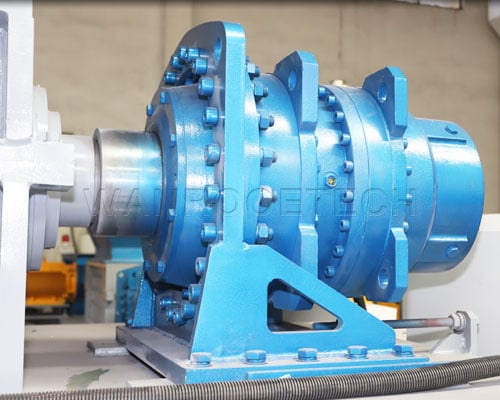

Hydraulic Force Feeder(optional) A hydraulic force feeder is available to actively press the input material down into the cutting zone between the two shearing shafts. This holding action prevents material from riding over the blade hooks, thus greatly improving the cutting efficiency and throughput of the machine. | Planetary Reducer The reducer chassis adopts welded box, helical gear, planetary gear transmission, with small volume, low noise, high torque and other characteristics, higher transmission efficiency. |

|  |

Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Rotary Screen(optional) To effectively control the output product size, a circular screen mounted around the cutting chamber is the ideal solution.The rotary screen runs at low speed, the oversized fractions are recirculated back to the cutting chamber for further shredding, whilst the sized fraction falls through the screen to the next process. |

Car Truck Mobile Tire Shredder Machine Waste Tire Tyre Recycling Machine Technical Features:

This shredder adopts an environmentally friendly design concept, with no pollution, exhaust gas, or waste retention during the production process. It has a compact structure, occupies a small space, is easy to maintain, and has low energy consumption, making it a cost-effective investment. The machine is equipped with a powerful engine, a long working length, and a large feeding volume. Two cutting rotors ensure efficient feeding. The intelligent PLC controller can sense overload caused by foreign objects, automatically stop and reverse to clear, and protect equipment safety. The screen design meets the customized output size requirements of customers. Tool disassembly and replacement are simple and safe. Specially using a planetary gearbox, it has high efficiency and strong stability, providing an ideal choice for tire recycling and processing.

Car Truck Mobile Tire Shredder Machine Waste Tire Tyre Recycling Machine Application Areas:

•Civil Engineering Applications: They can be used as landfill gas trench collection walls, as backfill for road landslide repair, as vibration-reducing material for railway lines and as backfill for maintaining walls.

•Ground and Crumb Rubber: For example, it can be used in paving projects or be molded into products. Common examples of rubber molded products include carpet padding, rubber flooring materials, patio decks, livestock mats, movable speed bumps, sidewalks, dock bumpers, railroad crossing blocks just to mention but a few.

•Carbon Source: Instead of using coke or coal in steel mills, rubber can be used as a source of fuel. In fact, studies have recommended that steel mills should adopt the burning of rubber as fuel instead of coal since coal is mined and can be depleted. Using rubber as fuel is an excellent way for these mills to go green and reduce their carbon fingerprints.