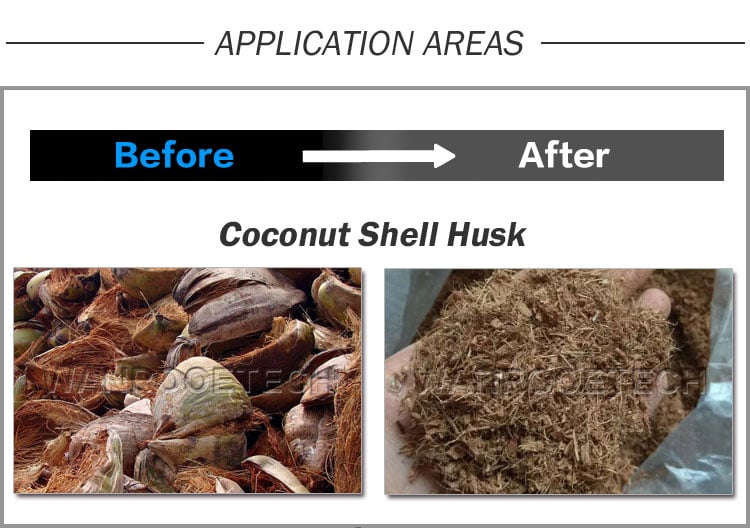

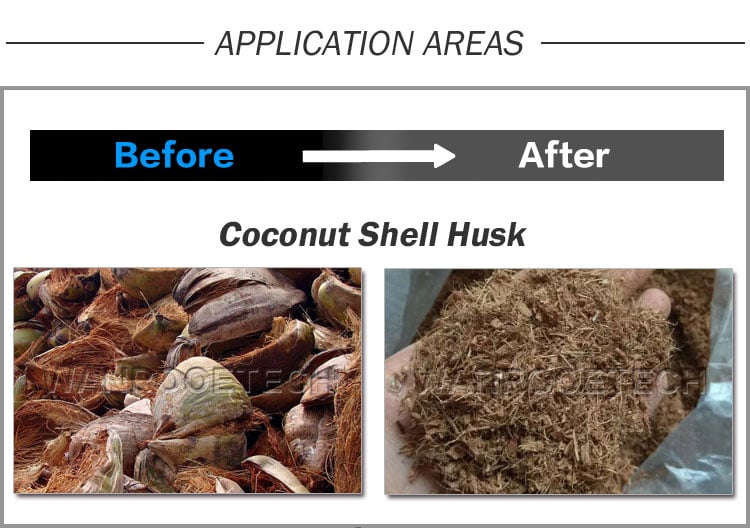

Single Shaft Coconut Fiber Coir Coconut Husk Shell Shredder Machine Application Areas:

Single Shaft Coconut Fiber Coir Coconut Husk Shell Shredder Machine can shred a variety of materials, such as biomass, branches, leaves, straw, corn on the cob, coconut shell, palm husk, straw, bark, banana tree, straw, garden waste, etc.

Coconut husk shredder in coconut husk recycling

After being chopped, coconut shell exhibits diverse application potential. It can not only be made into high-strength and environmentally friendly solid building boards with 100% fiber shell, replacing traditional wood or plywood, but also widely used in fields such as construction and automotive manufacturing (such as flooring and particleboard). It can also be used as a soil amendment, mixed into the soil around plants to maintain moisture, or further processed into coconut shell activated carbon to improve soil quality, increase soil CO2 content, adsorb harmful metals, and enhance microbial activity. In addition, coconut shell fragments have been innovatively used to make pillows, mattresses, carpets, doormats, cleaning brushes, flower pots, car trunk liners, bed liners, floor coverings, wallets and other daily necessities, fully demonstrating their extensive and practical value.

Single Shaft Coconut Fiber Coir Coconut Husk Shell Shredder Machine Description:

The Single Shaft Coconut Fiber Coir Coconut Husk Shell Shredder Machine uses the interaction of movable cutter heads and fixed knives to tear, cut and extrude the material into small sizes. It can be available for shredding a wide range of materials including plastic, wood, rubber, and paper, etc. The cutter head is consists of a basic shaft and pieces of quadrangle cutter. There are four edges that are easy to change. 'V' shaped rotary cutters are fixed on a single shaft. The fixed cutter is mounted at an angle adjacent to the rotary cutter to achieve better cutting. The material is grabbed between 'V' shaped rotary cutters and fixed cutter shreds repeatedly. During the grinding process, the evenly cutting, saving of energy and reduction of noise is ensured by the installation of 'V' shape rotor knives. Also, the knives are very easy to install and remove.

Single shaft shredder Blade:

Single Shaft Coconut Fiber Coir Coconut Husk Shell Shredder Machine Components:

|  |

Hydraulic-driven swing pusher To push the objects close to the rotary cutters to achieve efficient shredding performance | Heat treated rotor knives Special DC53 steel (hardened) four edges use before the replacement |

|  |

V-cutting rotor design with staggered cutter positioning | Wear Resistant Tungsten surface coating for abrasive applications |

|  |

Easy operation Simply press the buttons on the control panel to control every movement, and "auto mode" can be selected on the control panel for fully automatic operation | Replaceable screen at the outlet For controlling the output granules below certain size. Size of the screen mesh can be customized according to your need |

|

|

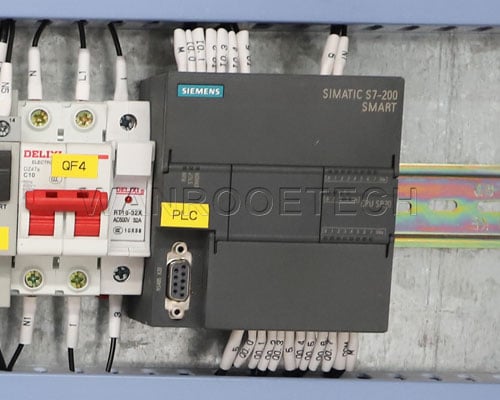

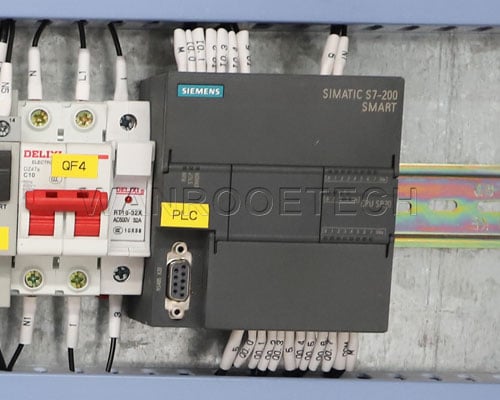

PLC control Making it easier for fault diagnosis and maintenance | Hydraulic System The pressure and rate of flow can be adjusted according to different materials. |

Single Shaft Coconut Fiber Coir Coconut Husk Shell Shredder Machine Features:

1)Precisely processed combined frame made of extra-thick plates; Lange-angle, hexagon prism of power slewing axis; Big hopper with big caliber for feeding big material

2)PLC control system with automatic overload protection and auto-reverse switch

3)Unique hydraulic pushing system accelerates the shredding speed, for light material particularly

4)Each dynamic blade has four cutting edges which enable reutilization after being abraded, by rotating 90 degree

5)Each fixed blade has two cutting edges which enable reutilization after being abraded, by rotating 180 degree

6)Quiet operation at low speed

7)Screen perforation is adjustable according to customers' requirement

8)The shredders can be adjusted according to customer-specific requirements for throughput volume, material to be processed, etc.