Hazardous clinical waste autoclave shredder machine Introduction:

Hazardous clinical waste autoclave shredder machine is our company according to the following State Environmental Protection Administration issued a "high-temperature steam centralized medical waste treatment project technical specifications(Trial) file for the special requirements of sterilization equipment development and production of high-grade medical waste sterilization device.

According to "People's Republic of China Environmental Protection Law',"People's Republic of China Solid Waste Pollution Prevention Law" and "Medical Waste Management Regulations, the machine can be used at all levels of medical institutions for infectious medical waste crushing and off bacteria.

Hazardous clinical waste autoclave shredder machine features:

1. Set in one crushing and high-temperature sterilization, sterilization after the first break, compact design suitable for a variety of occasions;

2. Crusher lower mounting, double shaft structure;

3. Crusher housing assembly using split structure, easy maintenance;

4. Gate drive-by cylinder structure, obstacles automatic back;

5. After the door is closed by cylinder lock in place to protect and ensure the safety of the operation;

6. Seal the door when a power cut, such as failure, you can still remain sealed;

7. In the sterilization of waste, while air and water sterilization process also simultaneously generates sound processing.

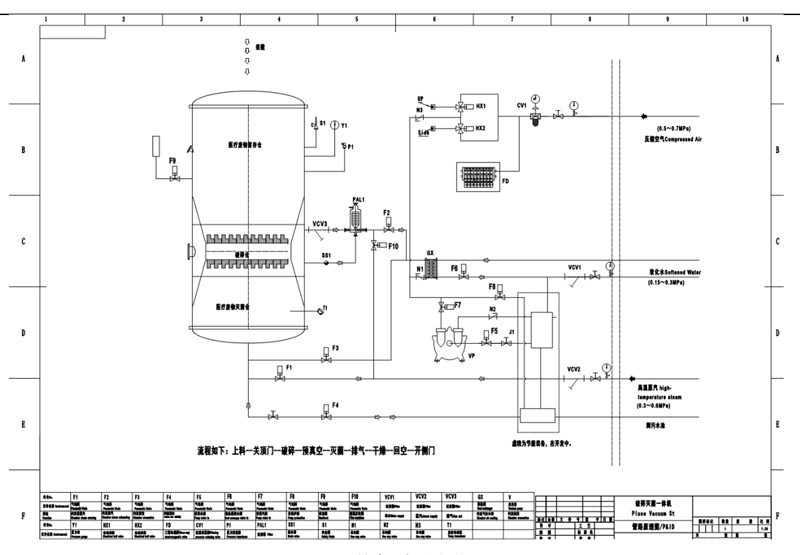

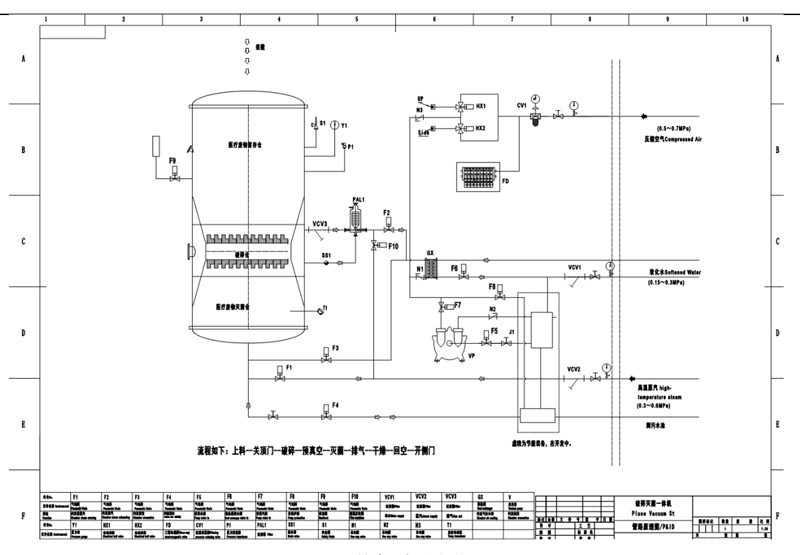

Hazardous clinical waste autoclave shredder machine equipment components:

1. Autoclave shredder machine by the body, sealed doors, stirring mechanism, broken bodies, piping systems and control systems and other components

2. Body stainless steel circular vertical structure.

3. Inner surface after mechanical polishing automatic polishing machine, smooth surface roughness Ra≤0.8 micron, and finally through the electrochemical polishing, surface passivation film, bright clean slide, corrosion resistance, and durability.

4. Circular ring sealed doors, air sealing structure, open the door driven by cylinder, and a safety interlock.

5. Pipeline system from the control valve, high-precision biological filters, pumps, booster pumps, safety and sanitary piping and other components.

6. SIEMNES control system used in Germany as the main controller of the new PLC, Siemens touch screen as the user interface, Germany WIKA pressure transmitters and other components pairs consisting of a complete control system.

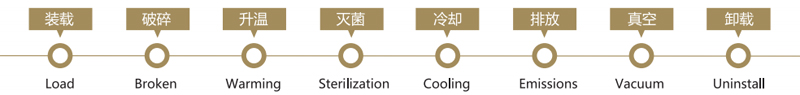

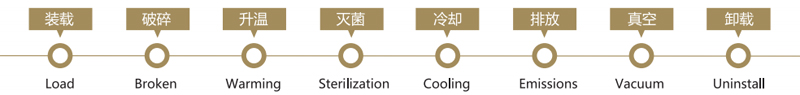

Hazardous clinical waste autoclave shredder machine Process:

Medical waste into the cavity from the top of the door seal after full top seal the door closed and locked, the operator has to run one machine preset sound processing program, the program is run as follows:

1. Load: After feeding the material through the fill material hoist closed;

2. Broken: Gear motor drive shaft counter-rotating blade, blade material through cut, shredded and squeezed, crushing processing; range for sterilization of the waste.

3. Heating: After the completion of the start crushing inward into the steam chamber through the exhaust valve open intermittently,

4. Sterilization: After reaching the sterilizing temperature sterilization start timing, in the chamber during an intake valve by the temperature and pressure within the chamber is controlled to ensure that the common chamber is kept within a certain temperature range for sterilization of the waste.

5. Cooling: After the sterilization time, the inner chamber to discharge into the cooling liquid, cooled to a set temperature;

6. Emission. The bottom discharge valve is opened, the water inside the discharge chamber, the pressure within the chamber drops to the set value, the program branches drying stage;

7. Vacuum: Vacuum pump open internal chamber was evacuated, while the interlayer to maintain a certain pressure and temperature, play a role within the drying chamber;

8. Uninstall: Open the door at the bottom of the material and the material backstop unloads the material to the material transfer vehicle.