Heavy Duty Plastic Waste Garbage Shredder Description:

The plastic waste garbage shredder is being used for multiple purposes including the reduction of waste materials like solid waste and municipal solid waste (MSW). These are also known as waste shredders or waste crushers and deploy the use of heavy-duty shredding machines for the purpose of waste reduction.

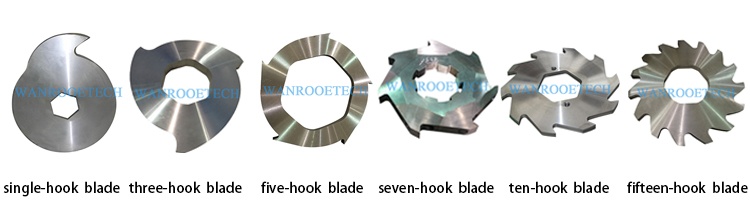

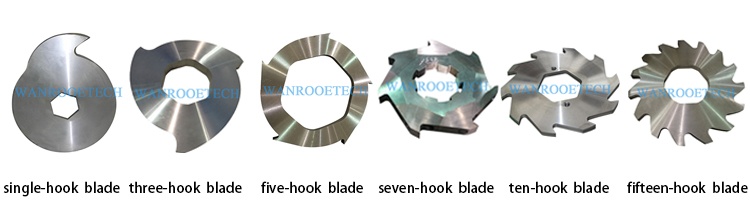

Heavy-duty plastic waste garbage shredder with loading hoppers, equipped with high-quality cutters with low rotation speed for lower energy consumption and noise reduction. It incorporates two counter-rotating shafts that intermesh with each other(2 shafts with sharp elements constituted by sharp-corners disks provided with hooks; every hook has the task to hook the product and drive it by the action of the two counter-rotating shafts). The material is powerfully torn and shredded by the talons of the cuttings discs. Specially designed rotor makes the shredder be extremely worn-resistant.

Double Shaft Shredder Blades (According to different materials choose different blades ):

Why is there a Need for plastic waste garbage shredders?

With the recent increase in population and pollution levels, the amount of waste that is being generated has multiplied. As the amount of waste being produced has increased, so has the cost for landfills. As such, there was a strong need for a revolution in the same. Owing to the seriousness of the issue, the scientists developed the size reduction machines named waste shredder or waste crusher.

How do plastic waste garbage shredders function?

During the working process, after the motor starts, the driving blade begins to rotate. Plastic waste is fed into the shredding chamber through the feeding port of the shredder. The feeding port is equipped with fixed blades and moving blades inside, which cooperate with each other to form shear and tearing forces. When plastic waste comes into contact with blades, it is subjected to strong shear and tear forces and is broken into small or fine pieces.

In addition, the shredder is usually equipped with a filter or screen inside, which is used to screen and separate the crushed plastic particles, removing particles or impurities that do not meet the specifications. In this way, it can ensure the uniformity and size controllability of the discharge to meet the subsequent recycling or reuse requirements.

How are plastic waste garbage shredders Useful?

With the rocketing amount of waste generated from the day-to-day activities of human beings, the waste needs to be minimized to sustain life on this planet. Hence, many companies use waste shredders to eliminate this problem. Some of the fundamental advantages of using this waste shredding machine can be:

– Reduction of biodegradable and non-biodegradable wastes to smaller pieces.

– Making the landfill process efficient and less troublesome.

– Reducing the pressure on the Earth’s natural resources.

– Recycling of the waste materials for reuse by the people and industries.

– Less power and fuel consumption to maximize energy efficiency.

– Cost-effective as the method of waste reduction with the use of waste shredder is highly affordable.

– Making the Earth a sustainable place to live in for future generations.

– Increasing the profit of the companies and industries by reducing the waste materials and reusing them for some other purposes.

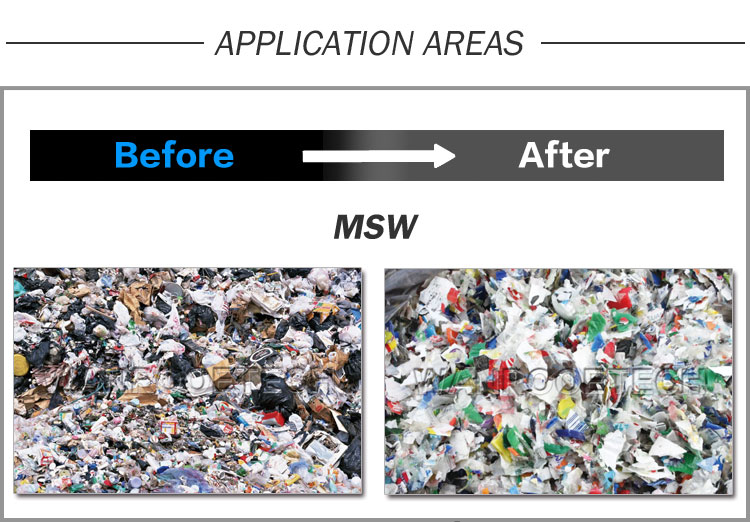

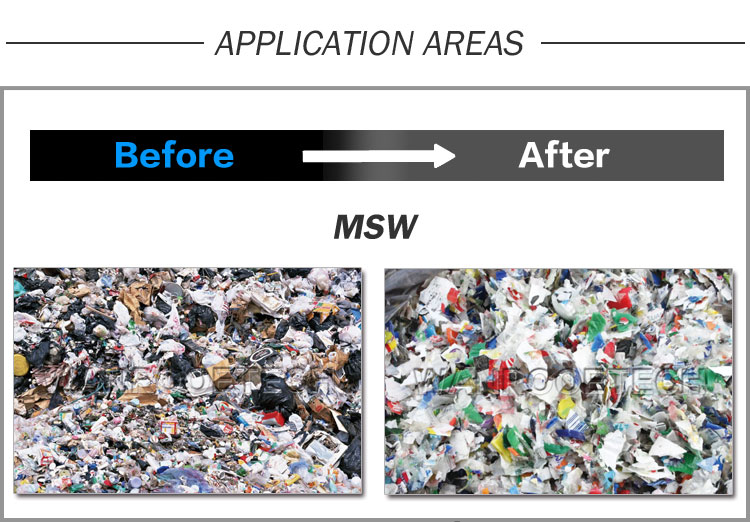

Heavy Duty Plastic Waste Garbage Shredder Application Areas:

The heavy-duty shredder machine can easily pre-crush:

•waste plastic, such as plastic sheets, plastic bottles or canisters;

•electronic waste and waste household appliances;

•scrap (components, subassemblies; consumables);

•metals(lead, aluminum, copper, cable, barrels, sheet scrap, sheet metal pieces left over from production processes);

•aluminum cans;

•wood(wooden pallets or fruit boxes);

•waste tire, rubber;

•paper waste (cardboard, newspaper, office paper, books, magazine, kraft paper, paper core, cardboard tube, paper packaging material);

•textiles (rags, garments, carpet);

•animal bones and organic waste.