PET Flakes Plastic Recycling Pelletizing Line Description:

This pet flakes pelletizing line is used to make PET plastic flakes into pellets or granules.Twin screw extruder recycling & pelletizing system are applied to the waste materials, which need high processing performance of melting, volatilization, filtering, etc., mainly works for the job of PET scraps recycling and re-pelletizing.

After processing techniques such as feeding, heating, melt, cooling, drying, cutting, etc., the final products are PET plastic pellets/granules that can be to produce new PET plastic products.

PET Flakes Plastic Recycling Pelletizing Line Process flow:

Screw feeder ( OPTHIONAL)→ Force feeder→ Parallel twin screw extruder →Hydraulic filer exchanger→ Mould head →water cooling tank →Plastic standard cutter→ Finished product packing.

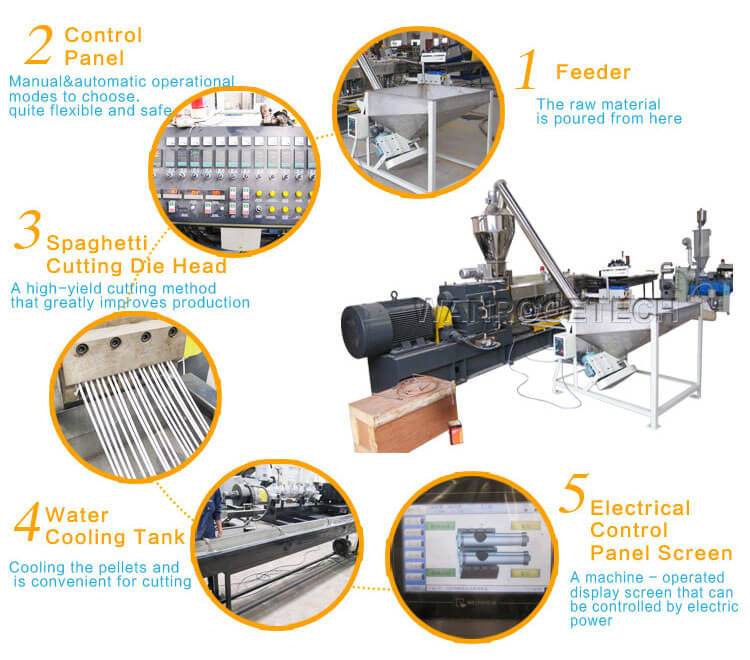

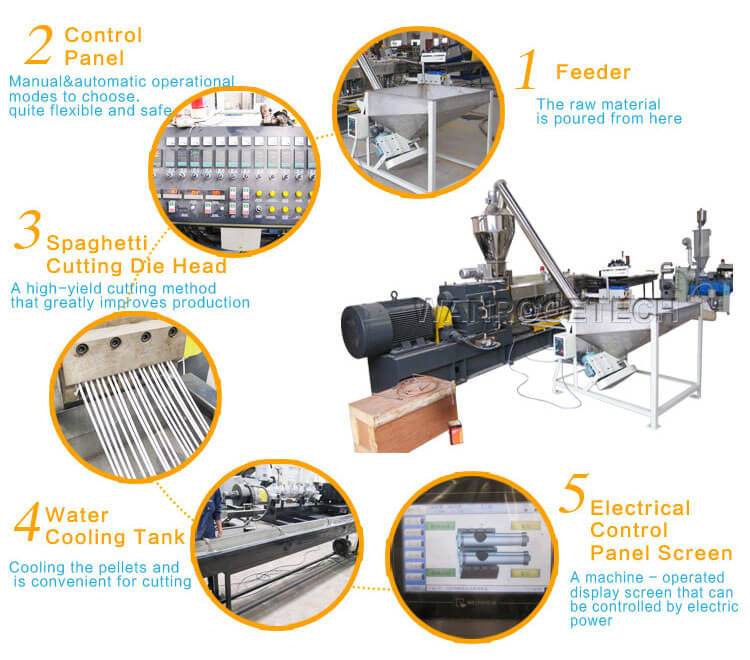

PET Flakes Plastic Recycling Pelletizing Line Components:

Detailed description of each item:

1.Screw Feeder: convey Plastic scraps into the main machine.

2. Force feeder: feed the material to the extruder with a designed speed, the speed can be adjusted

3. Parallel twin screw extruder: plasticizing material and exhausting gas.

4. High speed Net exchanging system and Die-head: filter material impurity, to make production more stable.

5. water tank: cooling the PET noodles

6. Plastic standard cutter: cut the PET noodles into granules.

PET Flakes Plastic Recycling Pelletizing Line Equipment List:

1 | Screw Feeder (OPTHIONAL) |

2 | Force feeder |

3 | Parallel twin screw extruder |

4 | Die head and screen changing device |

5 | Water tank |

6 | Air -knife |

7 | Electrical control box |

PET Flakes Plastic Recycling Pelletizing Line Features:

The PET sheet recycling and granulation production line integrates screw free rapid assembly, wide adaptability to raw materials, and diverse die cutting. It ensures stable production through an efficient feeding system and uses vacuum exhaust screws to improve particle quality and reduce failures. This series of design features makes the production line perform excellently in plastic recycling processing, not only efficient and flexible, but also energy-saving and environmentally friendly, becoming a highly respected preferred solution in the industry.

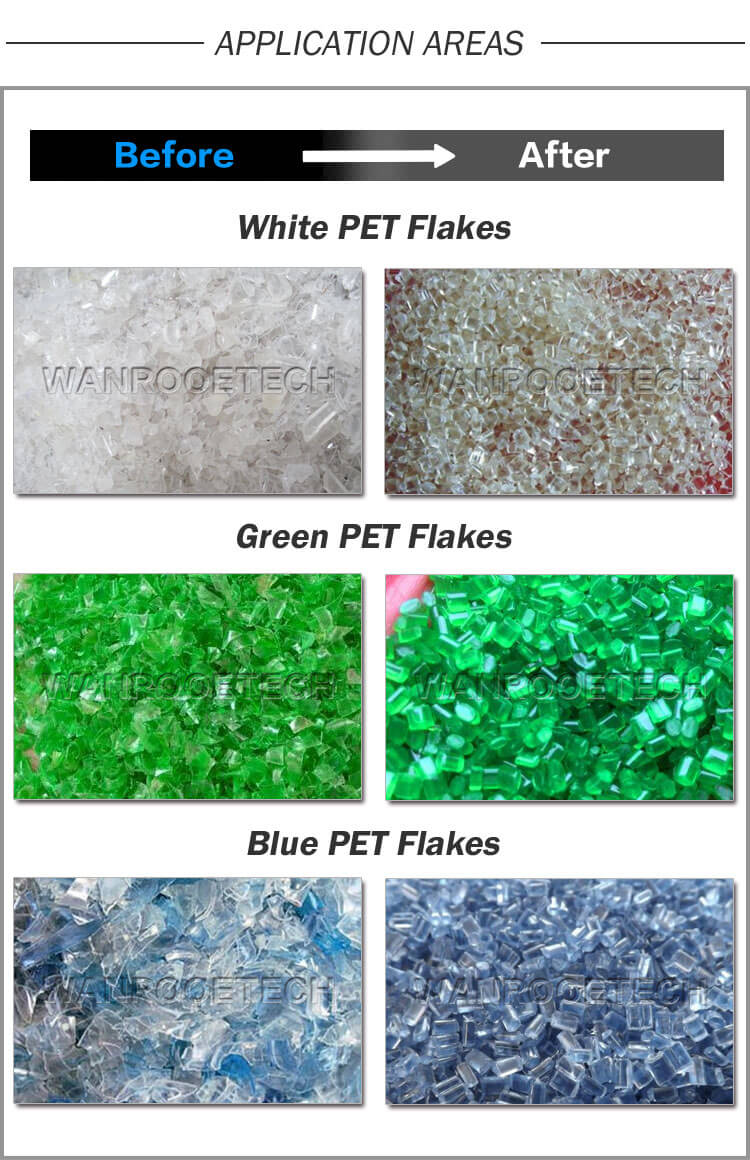

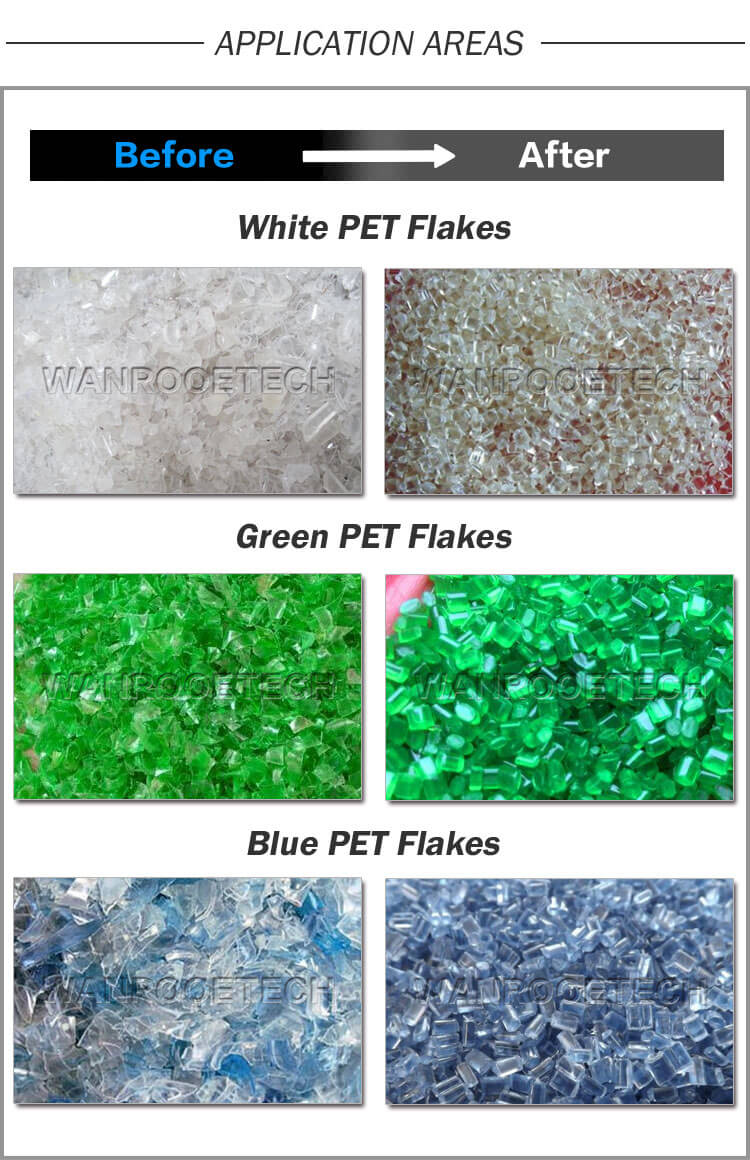

PET Flakes Plastic Recycling Pelletizing Line Application :

PET plastic pelletizing line is designed specializes for recycling the recycled washed plastic PET plastic flakes/scraps, such as Cola plastic bottle flakes/scraps, purified water bottle flakes/scraps, PET sheet flakes/scraps, PET drinking bottle flakes/scraps, etc.