Application:

The design of cold press CPE CPP BOPA PET film scrap granulator has good reliability, maintenance and stability, and is specially used for granulation recovery of CPE,CPP, PE, PO, PP, BOPA, PET, PVC and other thin film edges.

Structure introduction:

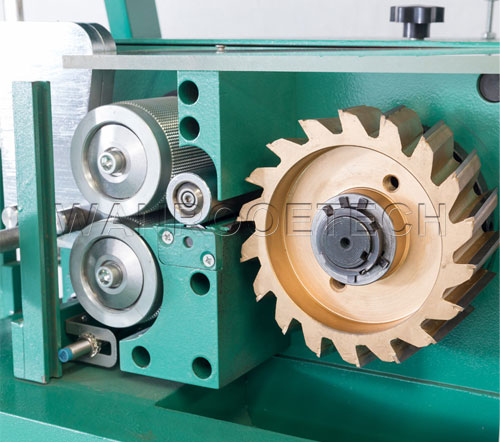

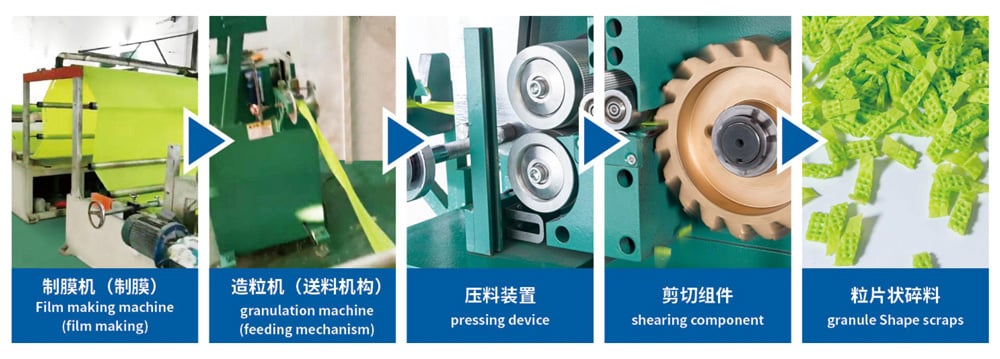

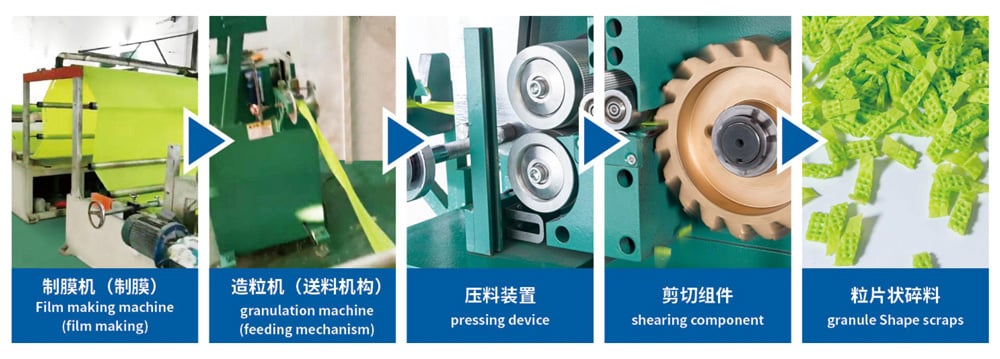

The cold press CPE CPP BOPA PET film scrap granulator machine consists of the following components: an electric mechanism, feeding mechanism, pressing device, transmission system and shear component.

Working principle:

When the film scraps are spit out from the film making machine, they are immediately sent to the feeding mechanism of the granulator. The feeding mechanism sends the materials to the pressing device. After the materials are compacted, they are then transferred to the shearing assembly to shear the materials into Crushed, bagged and completed for recycling.

This cold press CPE CPP BOPA PET film scrap granulator does not require heating and consumes a small amount of electricity (3KW). It directly compacts the plastic and then cuts and pellets it. The plasticizing performance of the product remains consistent with that of the original film without changing the chemical composition of the material. It has low noise and no dust. Because the granular specific gravity is not much different from that of plastic granules, 30%-40% can be added. It is not easy to cause bridging and the product is not easy to have crystal points. This machine is an ideal replacement for crusher regenerators.

Features:

Because cold press CPE CPP BOPA PET film scrap granulator machine presses the film directly and does not change the chemical composition, the granular product can be recycled efficiently. The main motor Cai Yong frequency converter adjusts the speed, saves energy, can adjust the speed steplessly, is conducive to environmental protection, simple structure, is easy to operate (single-person operation), and has a high degree of automation.

Film edge material input transmission system transmission

1. Associated with the film machine, in the process of membrane mechanism filmmaking, the removed film edge material can be immediately fed into the feed mechanism of the granulator. The feeding mechanism inputs the material into the press device, and irregular edge kerats are pressed into a neat pattern belt, and then transferred from the transmission line system to the shear component, shears into granular fragments, and completes instantaneous recovery.

2. Because of the cutting machine: the edge material cut by the cutting machine is rolled onto the paper core, and the rolled material is sent to the granulator for granulation.