Description:

Iron removing machine, also known as magnetic separator, Permanent magnetic dry magnetic separator. Generally refers to a non-metallic magnetic separator, which removes iron and other magnetic materials from raw materials, and is often used in ceramics, mining, chemical, grinding, and other industries. For example, in the recycling of plastics, the raw materials are generally rough-selected using a magnetic separator, and the iron content of the raw materials after the rough selection is reduced to a certain level, which can be used by certain industries that do not require high iron content. Where the requirements for iron content are high, it is necessary to use an iron remover to select and remove iron from the raw materials after coarse separation, or even to remove iron multiple times to meet the requirements. The iron removing machine can also be understood as a small magnetic separator. Usually, the iron removing machine is also used when the raw material processing capacity is not large.

Features:

1. Overband Magnetic Separator provides deep reaching magnetic circuit design to penetrate heavy product burdens.

2. Strong magnetic field intensity, high gradient and strong attractive force.

3. The unique stainless steel plate-armored belt can protect the belt from damage by sharp ferromagnetism material.

4. Non-excitation and self-cleaning will bring us energy saving and convenience in operation.

5. Overband Magnetic Separator has self-adjustment function and the special sealed bearing block ensures the stable working of suspended overband magnetic separator in harsh environment.

6. Safe specification meets the international standard.

Installation:

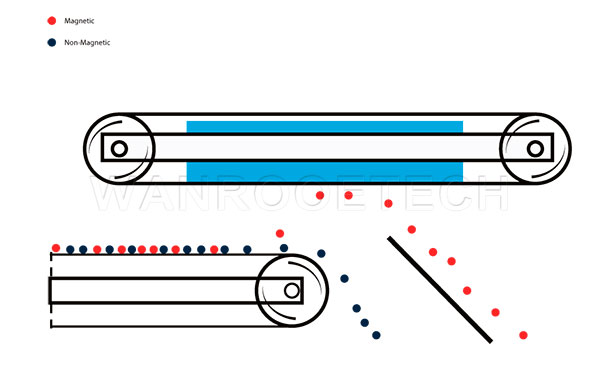

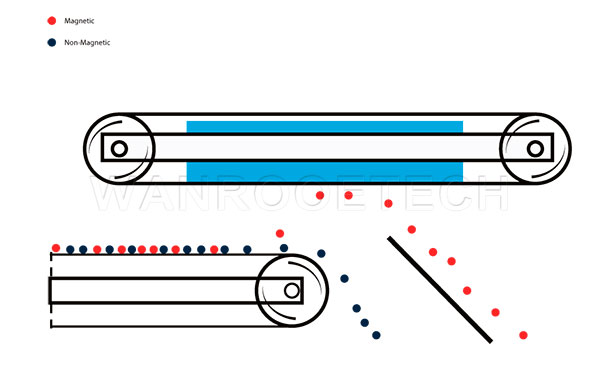

Most commonly the overband magnetic separator is suspended above and across the belt, however, it is also possible to place it at the head of the conveyor (parallel to the belt). The kind of applied magnets depends on the position of the separator: if the magnetic separator is parallel to the conveyor belt, it is possible to use weaker magnets (as at the end of the conveyor belt the material is quite loose). On the contrary, if the magnetic separator is suspended across the belt, we recommend that stronger magnets are applied (as the material layer on the belt might be higher and compacter)

The standard version of the overband magnetic separator DND-AC M is fitted with strong permanent ferrite magnets. However, if you need stronger magnetic force (e. g. for mobile lines, grinders, mills), we recommend that the overband magnetic separator is equipped with extremely powerful neodymium NdFeB magnets from rare earth ores. A careful interference shielding ensures that the magnetic field is concentrated only on the material on the conveyor belt.