EVA Foam Scrap Recycling Pulverizing Machine Application:

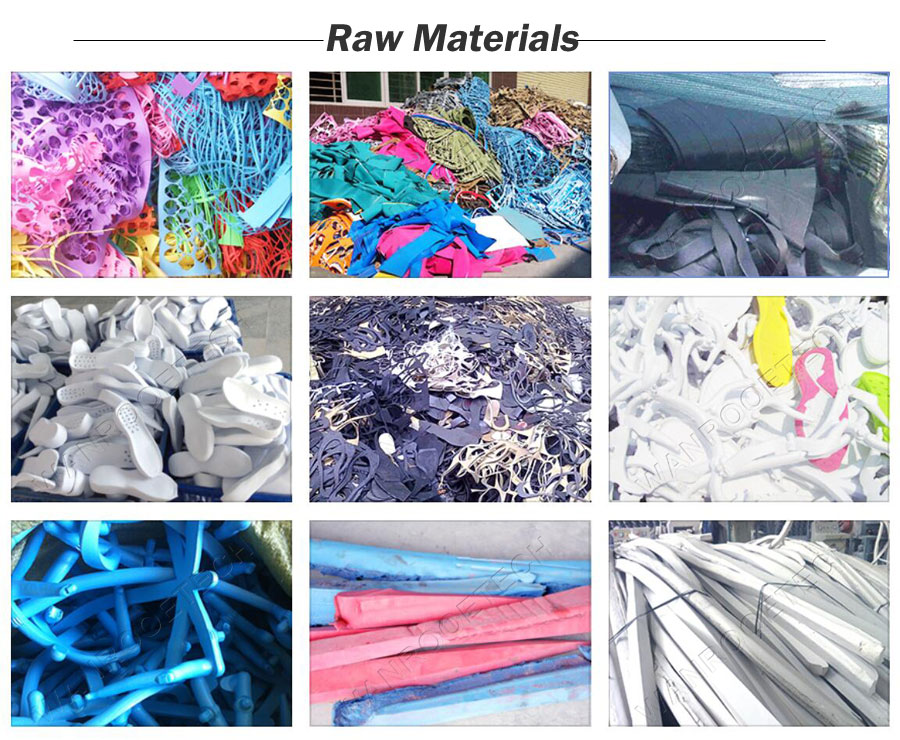

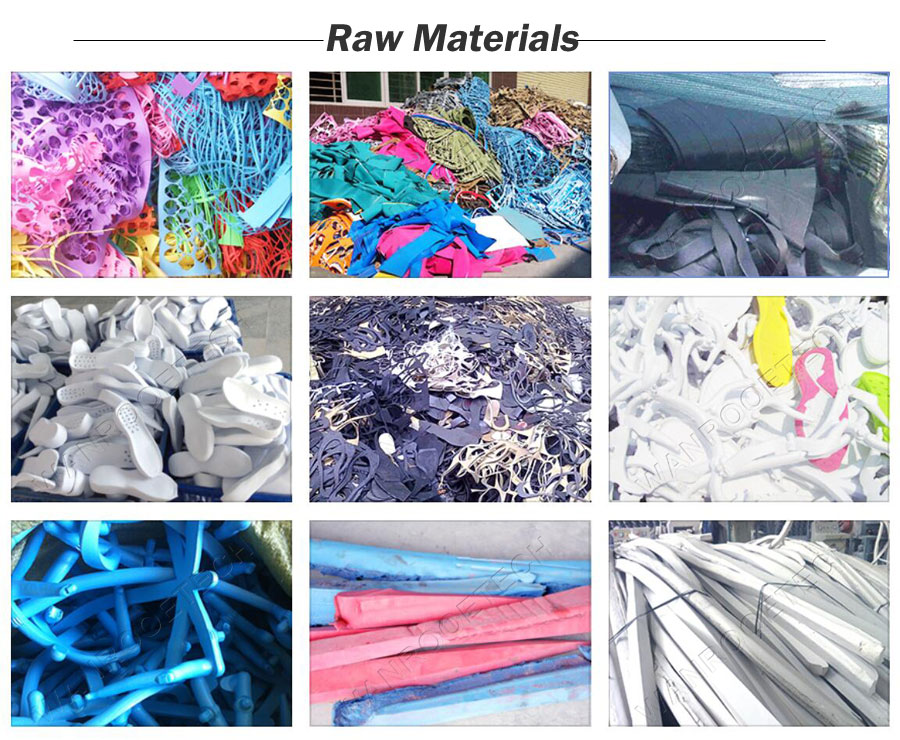

EVA Foam Scrap Recycling Pulverizing Machine is suitable for MD shoe sole foaming (EVA secondary high-pressure molded products), EVA sheet foaming, SBR foaming, RB (rubber foaming), PE foaming, NBR sponge foaming and other rubber and plastic foaming scraps which can recycling and utilization.

EVA Foam Scrap Recycling Pulverizing Machine Description:

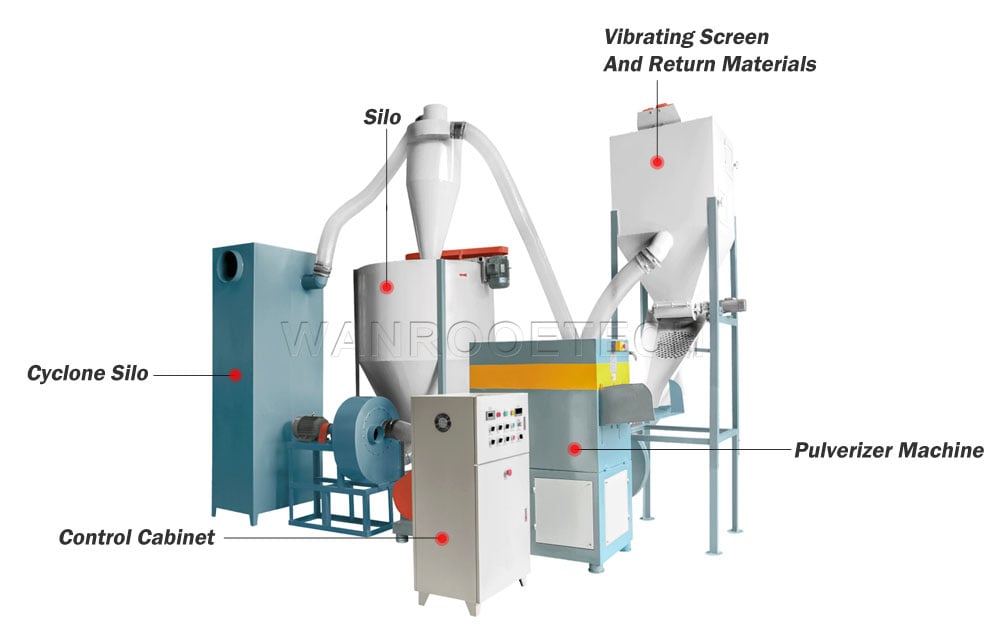

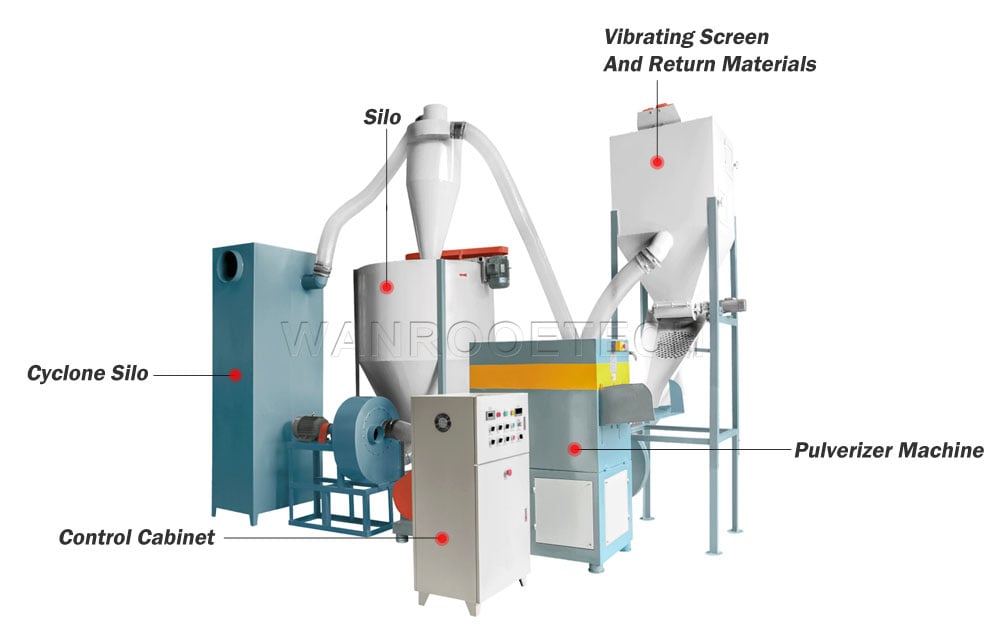

The EVA foam scrap recycling pulverizer machine is a new type of energy-saving, environmentally friendly recycling equipment. It is suitable for recycling EVA, SBR, RB, PE, sponge, and other rubber and plastic foam scraps, as well as EVA shoe material and sponge grinding. In order to achieve better dust removal effect, the EVA pulverizer machine needs to be matched with a chiller, frequency converter, and pulse dust removal system.

Recycling Style Comparison Between Traditional Recycling Style And Eva Pulverizer Machine:

| Project | Traditional style | New EVA Pulverizer | Efficiency |

| Electricity | Crusher Power 22KW, Open Mill Power 55KW, Total 77KW | 55KW | Save 22KW |

| 0perator | 3 people | 1 person | Save 2 person |

| Capacity | 100Kg/H | 120-180Kg/H | increase 20-80Kg/H |

| Kneading Time | 12-15Minute | 10Mintue | Shorten time |

| Electricity | 110KW | 40-50KW | Save 60-70KW |

| Temperature | 160℃ | 60℃ | Low temp protect material's property |

| Addition proportion | 10% | 30% | Reduce cost |

Traditionally, scrap recycling involves crushing the materials with a crusher and then mixing them into flakes with a rubber mixer. However, this process is not very efficient and can result in high temperature extrusion and reduced recovery rates. The new type of grinding mill used in the EVA pulverizer machine solves these issues. It features a high-speed, water-cooled integrated grinding wheel with a main motor of 45KW. This machine can work continuously for 24 hours and can be operated by one person. It directly grinds the leftover materials into powder, with a mesh size of 80-120 mesh and close to normal temperature (60 degrees). This ensures that the physical properties of the ground powder are not destroyed.

One of the advantages of the EVA pulverizer machine is its ability to add more powder in each batch of materials. This results in a higher addition ratio (20-30% compared to new materials) and allows for an increase of 3-5 mm per bed in the thickness of the foamed sheet. The ground powder also has a higher density and no color difference. Additionally, using the EVA pulverizer machine shortens the mixing time and reduces the likelihood of the mixing shaft breaking. These benefits greatly increase the output and can generate profits of more than 200 USD yuan for the company every day.

Feature:

Simple operation, no-crushed,un-extruding and mill the scrap directly.

Adjustable feed inlet, suitable for each size to feed, fits a silencer to cut down noise.

Extending feed inlet, have feed drive wheel, operation safe.

High-speed and water cooling roller make high production.

Powder grinded under normal temperature keeps its property have a better reuse effect.

New design, easy to install, simple operation.

Automatic return coarse material.

New systems, open mode, better cooling effect, higher powder rate.