Application:

Aluminium powder making machines are grinding materials that include zinc, copper, aluminum, raw and cooked iron scraps, aluminum foil, metal foil, metal alloys, stainless steel scraps, UBC cans, etc.

metal pulverizer machine application

Introduction:

The Aluminium powder making machine is a special equipment for processing raw iron scraps into iron powder. It adopts mechanical methods to directly grind granular or flake-like, sheet-like metal materials into fine powder. The equipment uses a variety of grinding principles, such as high-impact energy, vortex effect, and shear grinding.

The Aluminium powder making machine has a sieve to control the finished product rate and particle size of the discharge. External high-pressure blowers promote rapid material flow to reduce temperature rise. The external grading method allows for convenient and accurate particle size control.

The Aluminium powder making machine is suitable for ultrafine processing of zinc powder and copper powder, and coarse processing of aluminum powder and magnesium powder.

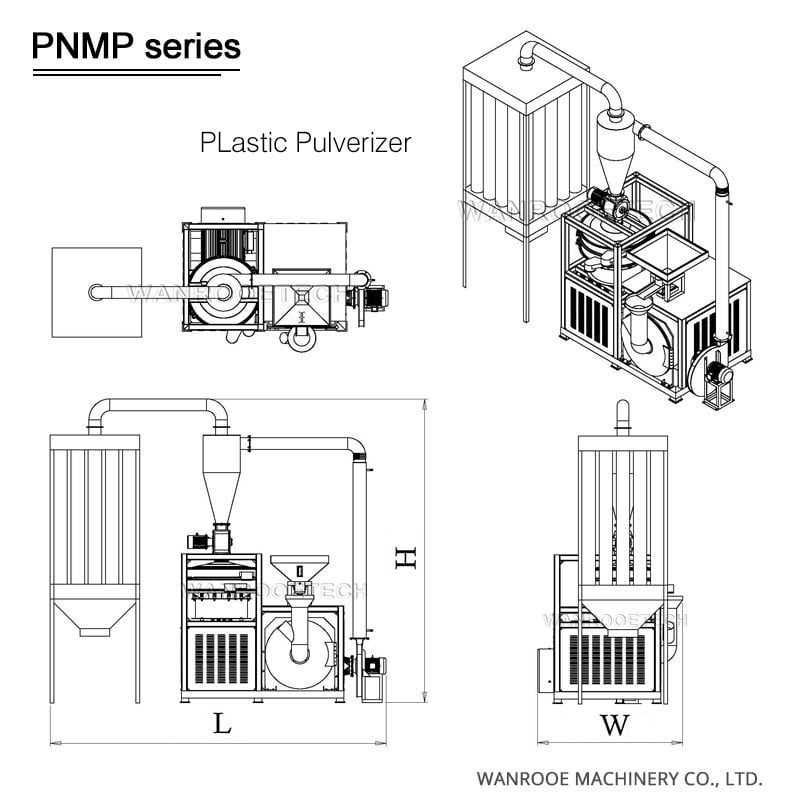

Structure of Aluminium powder making machine:

The Aluminium powder making machine is composed of a main machine, a main machine seat, a conveying pipe, a cyclone separator, a fan, bags type dust catcher, a precision electromagnetic vibration feeder, a storage hopper, a vibrating screen, a closed discharge device, and an electrical control cabinet.

Working principle of Aluminium powder making machine:

Metal raw materials are added to the storage hopper and fed into the grinding chamber of the main machine by an electromagnetic vibration feeder.

In the grinding chamber, the metal raw materials are crushed by a high-speed rotating rotor.

When the metal raw materials are crushed to the desired fineness, they are sucked into the conveying pipe by an external high-pressure blower and then enter the cyclone separator.

In the cyclone separator, the larger particles remain in the grinding chamber for further crushing, while the smaller particles are discharged by the closed discharge device at the bottom of the separator.

The separated gas is discharged into the simple bag filter by the fan and then discharged into the atmosphere after purification.

The material discharged from the closed discharge device is a mixture of particles, which is screened by a vibrating screen to obtain the finished product and coarse powder.

The coarse powder is returned to the main machine for further grinding.

Aluminium Powder Making Machine Components:

|

|

Vibration Loader the material is sent to the vibrating screen by vibration | Pulverizer Disc Turbo-type pulverizer disc, Widely used for recycling PVC, aluminum foil, metal foil, metal alloys, stainless steel scraps, UBC cans |

|  |

Pulverizer Blade Rotating and fixed blades, D2 or SKD-11 material, wear-resistant.The number of blades varies depending on the device model. | Conveying Pipe All 304 stainless steel, durable.Non-rusting, non-sticking powder.Double layer pipeline, water supply in the middle layer. |

|  |

Vibrating Screen Installation of screen according to the grinding mesh, continuous production, automatic classification and screening, easy to replace. | Intelligent Control Can be adjusted according to the actual situation simple operation, saving time and effort |

|  |

Bags Type Dust Catcher Smaller footprint, lower price, can reduce the workshop dust, customers with higher requirements for environmental protection can choose pulse dust catcher. | Pulse Dust Collecter(Optional) Collect dust from products during the grinding process to prevent pollution. |

Features of Aluminium powder making machine :

* The metal pulverizer machine is fully automated and easy to operate.

* The fineness can be adjusted to meet different needs.

* The raw materials are diversified, and diversified production can be realized.

* Low energy consumption, large output.

* Closed production, dust-free, less pollution.

* Durable materials, long service life.