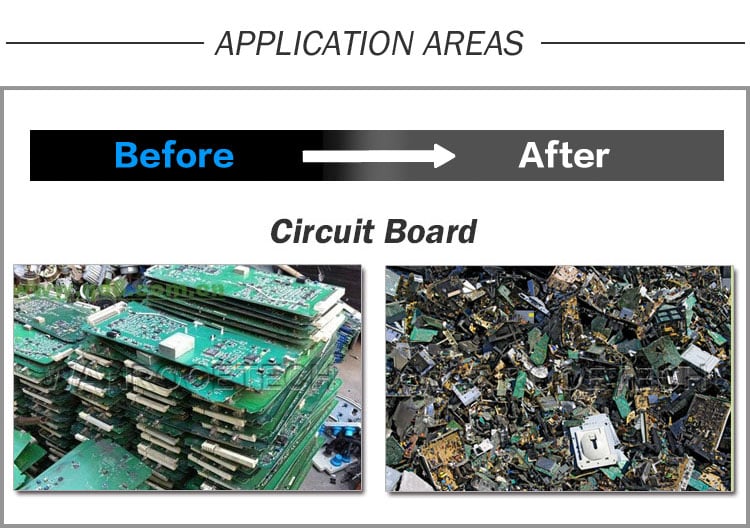

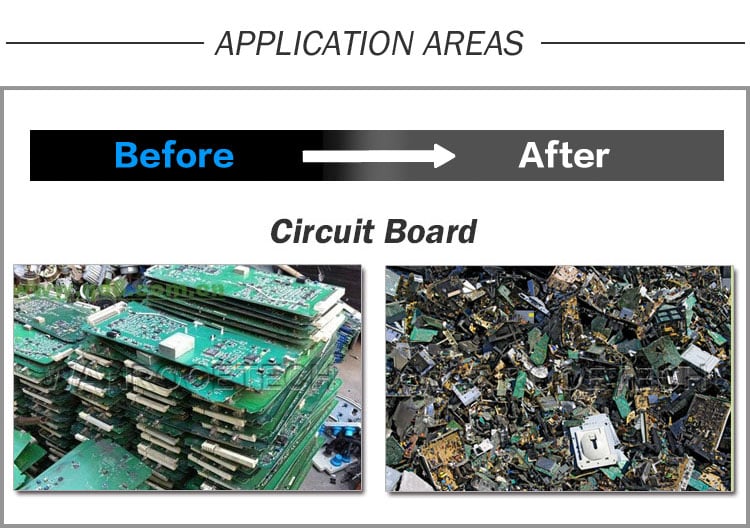

Scrap PCB Printed Circuit Board Shredder Machine Application:

Scrap PCB Printed Circuit Board Shredder Machine is used to recycle shred all kinds of printed circuit boards, such as computer boards, cell phone boards, TV boards, copper-clad laminate, and other household appliances.

Scrap PCB Printed Circuit Board Shredder Machine Description:

PCB Printed circuit board shredder is the very first machine to size reduce circuit board. Its infeed opening should be big enough to process tons of circuit board at the same time. During shearing and crushing of 2 rotors, circuit boards are broken down into irregular pieces.

Printed circuit board shredder is a primary machine to break down PBC in circuit board recycling. Worldwide, more than 40 million tons of electrical and electronic waste(WEEE) are generated every year – and the trend is increasing! Almost in each electronic device, there are at least 2 circuit boards regardless what the device is.

Recycling electronic equipment is not only worthwhile for environmental reasons but also often contains many precious metals that can be recovered in the recycling process.

Printed Circuit Board Shredding in a PCB Recycling Line

Printed circuit board recycling consists of shredding and separation. For the first shredding machine, we choose the double shaft shredder. After circuit board shredding, the particles are around 60mm by 60mm. Next, the second crushing machine is a granulator, resulting in 20mm particles. Then the shredded material is collected in a mesh box and processed further. The shredded PCB will be separated by the air separator and the electrostatic separator.

The whole metal recycling system has the advantages of unique structure, large output(500kg to 2000kg/hr) and power saving. The final material is separated into 99% pure copper, 98% iron and 95% plastics.

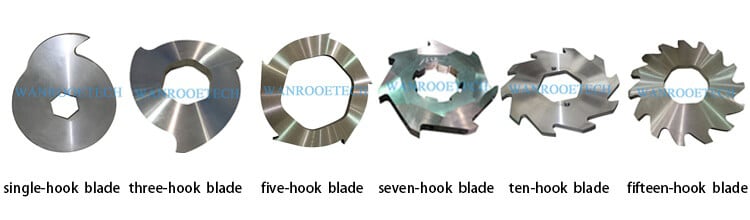

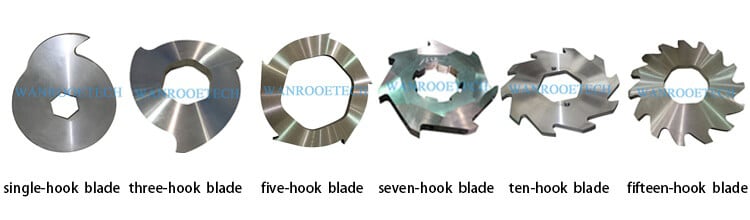

Double Shaft Shredder Blades:

Components:

|

|

Shredder Chassis The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

Hydraulic Force Feeder(optional) A hydraulic force feeder is available to actively press the input material down into the cutting zone between the two shearing shafts. This holding action prevents material from riding over the blade hooks, thus greatly improving the cutting efficiency and throughput of the machine. | Planetary Reducer The reducer chassis adopts welded box, helical gear, planetary gear transmission, with small volume, low noise, high torque and other characteristics, higher transmission efficiency. |

|  |

Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Rotary Screen(optional) To effectively control the output product size, a circular screen mounted around the cutting chamber is the ideal solution.The rotary screen runs at low speed, the oversized fractions are recirculated back to the cutting chamber for further shredding, whilst the sized fraction falls through the screen to the next process. |

Technical Features:

Main engine of double shaft shredding machine adopts high grade steel plate for welding, making sure the stability of equipment in long time heavy loading.

Shaft block adopts the patented detachable type, which makes it convenient to tear down the moving blade, fixed knife and other component quickly, and easy to maintain and replace the blade.

Moving blade adopts special alloy tool steel as material and uses precision forging machine to forge, and it is able to be re-used and repaired to use through multiple heat treatment and low temperature refrigeration treatment. While the stationary knife adopts the patented hook type installation, optimizing cutter changing function.

Cutter shaft is crafted from high-intensity and heavy-load dedicated steel, cooperating with cutter more reasonably to provide strong power for cutting.

Compared with single shaft shredder, the double shaft shredding machine can easily crush large size materials, like board, wood, tire and so forth.