Description:

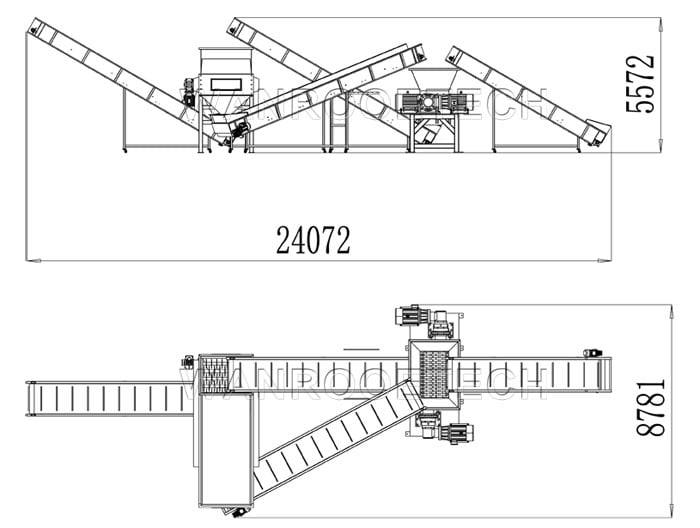

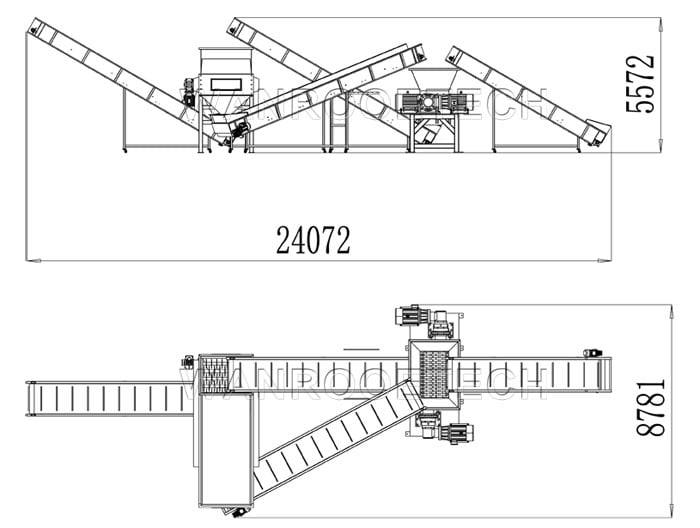

The TDF tire shredding Machine system is designed to produce up to 1.2-10 tons per hour of TDF. TDF systems produce a 25mm to 152mm(1''-6'') rubber chip, which is used as a coal additive for industrial boilers. Many of these facilities are turning to TDF because it burns hotter and cleaner than coal and is more cost-effective. Rough shreds can be outputted for use or processed further to remove steel from the rubber resulting in Wire-free TDF. This plant is made of two main parts: double shaft shredder and screen.

Components:

|

|

Shredder Chassis The whole chassis is made of welded steel plate and finely machined by CNC gantry milling, which has high bearing capacity, high impact resistance and more stable quality. | Shredder Spindle The shredder spindle is made of high alloy, forged and heat-treated and tempered as a whole, and then machined into hexagonal, octagonal and spline form by CNC gantry milling after fine turning, with long service life. |

|  |

Shredder Blade The shredder blade is made of special steel, forged, faded, refined, vacuum heat treatment, computerized wire cutting, CNC grinding machine processing. | Segmented Blades The segmented blade design can greatly reduce the blade changing time and cost. The blade comprises of the blade holder, and two types of blade segments, with and without hooks. Worn blade segments can quickly and easily be removed and replaced by simply removing the securing screws. |

|  |

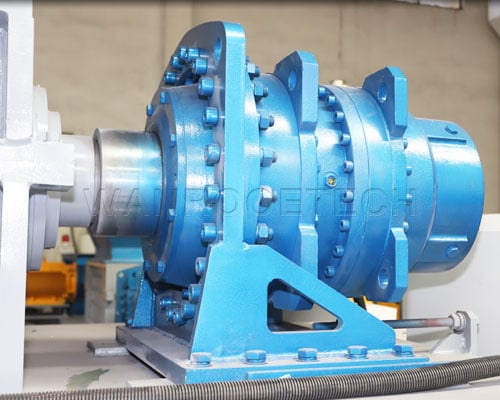

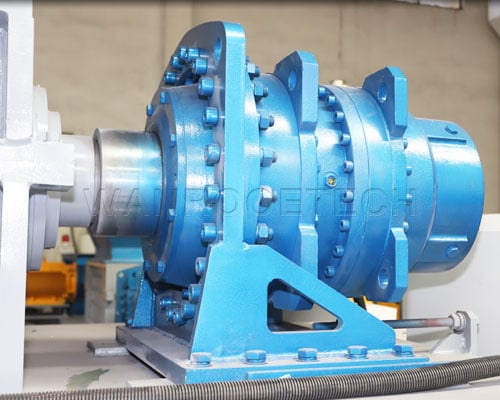

Motor The motor adopts Siemens, Wanan and other domestic brands of pure copper motor, with stable and reliable quality, and can be customized according to requirements. | Planetary Reducer The reducer chassis adopts welded box, helical gear, planetary gear transmission, with small volume, low noise, high torque and other characteristics, higher transmission efficiency. |

|  |

Roller Screen When the output is larger, the form of shredder plus roller screen can be chosen. Qualified materials will flow out from the gap between the rollers during operation. Unqualified materials move with the rollers to the conveyor belt for return material and repeated shredding. | Belt Conveyor The tire waste is conveyed into the shredder through the belt feeding device, and the speed of the conveyor belt is automatically adjusted according to the current of the shredder. |

Technical Features:

1、Efficient crushing: The TDF tire shredder can efficiently crush waste tires into small pieces or fragments, with high crushing efficiency and large processing capacity.

2、Material handling: The shredded material not only reduces its volume and increases its stacking density, reducing transportation costs, but also facilitates subsequent processing such as further processing, separation, and cleaning.

3、Low energy consumption: During the shredding process, the material is mainly subjected to the crushing effect of tensile and shear stresses. Compared to traditional crushers, which mainly bear compressive stresses, its energy consumption can be significantly reduced.

4、High crushing ratio: Due to the pulling effect of the opposite rotation of the crushing toothed rollers, the crushing ratio can reach about 300, which is much higher than the 3-5 of traditional equipment.

5、Forced discharge: The two rollers have a mutual cleaning effect and can automatically discharge any materials that are easily entangled on the moving parts of the ordinary crusher, such as sticky moisture, iron wire, steel bars, cloth strips, etc.

6、Strong durability: The moving blade of the shredder is made of alloy steel, which is durable and has a long service life. Meanwhile, the equipment has dust-proof characteristics and complies with environmental standards.

7、Automation control: The tire TDF shredder is usually automatically controlled by a microcomputer (PLC), with functions of starting, stopping, reversing, and overload automatic reversing. It is easy to adjust and has low maintenance costs.

8、Environmental Protection and Energy Conservation: By shredding waste tires and converting them into TDF (Tire Derived Fuel), reliance on traditional fossil fuels can be reduced, promoting a more sustainable and environmentally friendly energy production method.

Application Areas:

•Civil Engineering Applications: They can be used as landfill gas trench collection walls, as backfill for road landslide repair, as vibration-reducing material for railway lines and as backfill for maintaining walls.

•Ground and Crumb Rubber: For example, it can be used in paving projects or be molded into products. Common examples of rubber molded products include carpet padding, rubber flooring materials, patio decks, livestock mats, movable speed bumps, sidewalks, dock bumpers, railroad crossing blocks just to mention but a few.

•Carbon Source: Instead of using coke or coal in steel mills, rubber can be used as a source of fuel. In fact, studies have recommended that steel mills should adopt the burning of rubber as fuel instead of coal since coal is mined and can be depleted. Using rubber as fuel is an excellent way for these mills to go green and reduce their carbon fingerprints.