Aluminum Tin Beer Can Aluminum Scrap Shredder Machine Description:

Transmission system: Adopting planetary gear reducer to ensure stable and reliable power output.

Blade material: High strength alloy steel is selected, which is wear-resistant and durable, improving crushing efficiency and service life.

Inter axis operation: differential design, integrating tearing, squeezing, and biting functions, suitable for complex crushing needs.

Electrical control: Siemens component programming is used to achieve automatic detection and overload protection, ensuring safe operation.

Scope of application: Designed specifically for refining large and difficult to break aluminum materials, such as scrap aluminum, aluminum cans, aluminum strips, etc., it is also suitable for metal materials such as iron plates, scrap steel, copper plates, etc.

Discharge characteristics: Uniform discharge, controllable particle size, meeting diverse crushing needs.

Performance advantages: high efficiency, low speed, high torque, low noise, achieving dual protection of high efficiency and environmental protection

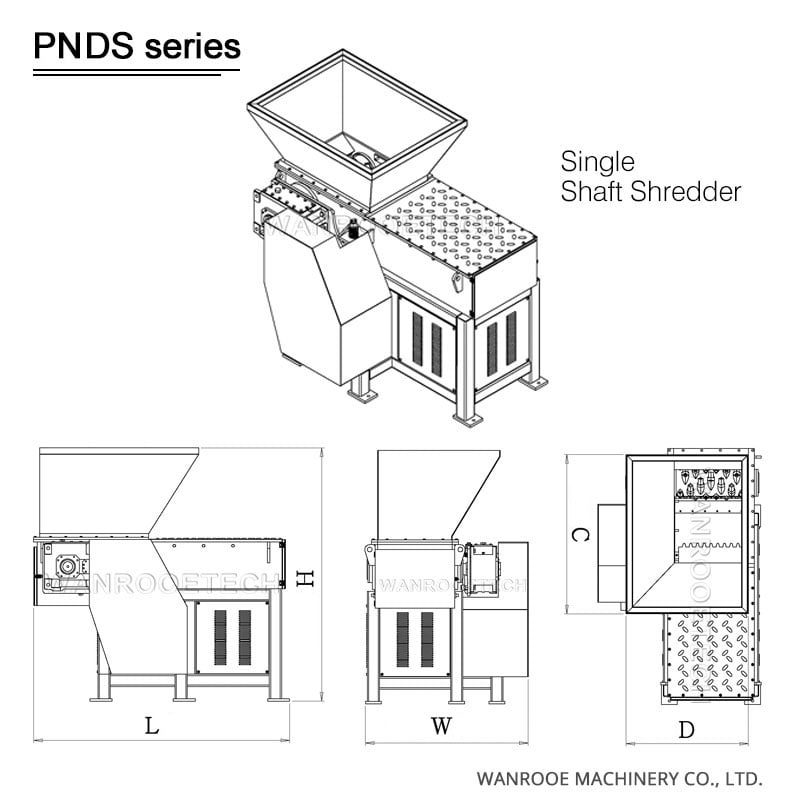

Single Shaft Shredder 'V' shaped blade

Aluminum Tin Beer Can Aluminum Scrap Shredder Machine Features:

1. Aluminum scrap shredder single shaft for plastic with the big feeding mouth can put the big plastic or rubber product freely.

2. The rotary and cutting blade with the edge of special design can get very high efficiency and high capacity.

3. The Aluminum scrap shredder single shaft for plastic is controlled by the PLC system; the blade can rotate in the opposite direction and close automatically if something unexpected happens; with very high safety service.

4. The single shaft aluminum scrap shredder for plastic runs slowly with low noise and is less dusty.

5. The blade material with special alloy steel made, with a long life.

6. All the machinery and electrical devices are protected in accordance with the European CE standard.

7. Hydraulic system Pushes the material automatically to the shredding rotor while working. More efficient and can achieve a high capacity. According to material kind, it can adjust the pushing speed to avoid overload.

8. Cooler system(optional) can maintain the temperature for continuous operation.

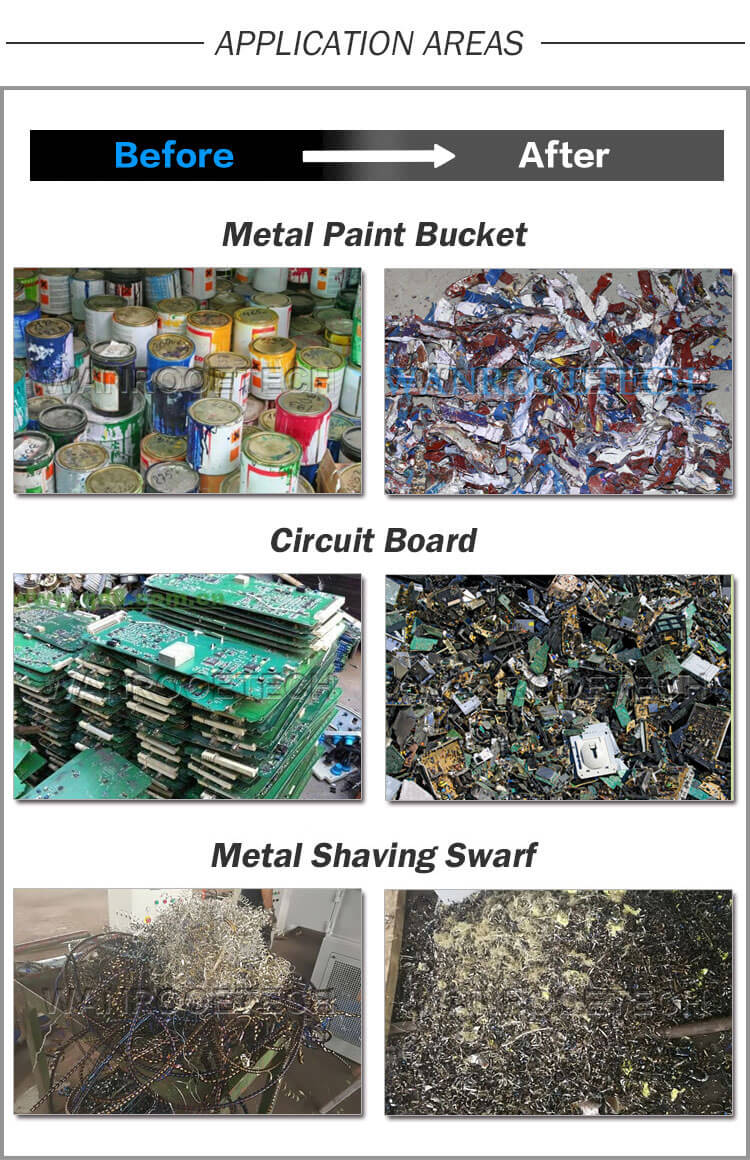

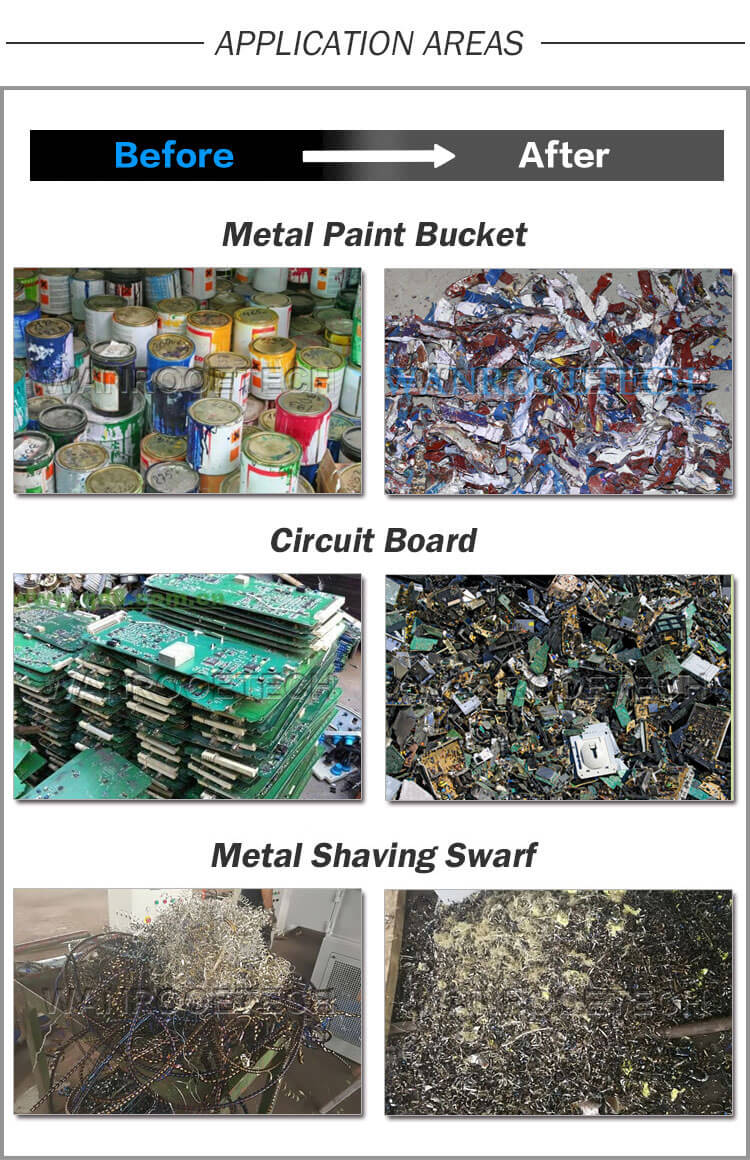

Applications of Aluminum Shredder Machine:

Scrap beverage cans (UBC), aluminum blocks and bundles, and soda cans: these items are the most common targets for aluminum shredders. Through the shredding process, waste aluminum beverage cans, aluminum blocks and bundles can be quickly crushed into smaller pieces for subsequent smelting and recycling, thus effectively saving aluminum resources and reducing environmental pollution.

Gas cans: Although gas cans themselves are not directly made of aluminum, their surface coatings or certain components may contain aluminum elements. Aluminum shredders are capable of removing coatings or crushing aluminum-containing parts when processing such items, facilitating subsequent material separation and recycling.

Spray creams, hairspray sprays, spray paints: These products often contain aluminum packaging or aluminum components (e.g. spray cans). Aluminum shredders can crush these packages or components to make them easier to recycle and process, and also help reduce environmental pollution caused by indiscriminate disposal.

Aluminum profiles, extrusions, plates and alloys: the edges, scraps or substandard products produced during the manufacturing process of these materials can be crushed by aluminum shredders. The crushed aluminum material can be directly used in the production of recycled aluminum, or as raw materials back to the furnace to rebuild, greatly improving the utilization rate of aluminum resources.

Aluminum wire, aluminum coil: Aluminum wire and aluminum coil are widely used in the field of electronics, electrical and communications, but their scrap can also be processed by aluminum shredder. The crushed aluminum wire fragments are convenient for subsequent separation and purification, which helps to realize the recycling of aluminum resources.