Waste Paper Recycling Pulping Machine

The waste paper recycling pulping machine is composed of a waste paper shredder and a pulping machine. It is mainly composed of a frame, a housing, a coupling, hammers, a screen, a belt pulley, a motor frame, a motor, and a feeding foil. The structure is simple and the layout is reasonable. The hammers are made of manganese steel with high wear resistance. The finished material size can be crushed into paper fluff according to the special screen holes inside. Waste paper recycling pulping machine is mainly used to crush waste paper from overseas into paper fluff for recycling as virgin pulp.

The production method of the waste paper recycling pulping machine is ingenious and the steps are simple. In view of the characteristics of the current domestic "waste ban", after simple processing of waste paper, it can be turned into waste paper pulp after preliminary processing (paper pulp is allowed to be imported in China), which can pass customs inspection. Moreover, the quality of the waste paper pulp after preliminary treatment is far higher than the waste paper recycled in China at present. Domestic paper mills can be mixed with virgin pulp directly without further processing, which is very effective and is deeply loved by domestic paper mills.

Applications:

The waste paper recycling pulping machine can be used for the recycling and pulping of paper tubes, paper cores, paper rolls, newspapers, cardboard boxes, waste paper boxes, packaging boxes, hard paper, corrugated paper, paper mill waste, high-grade paper, yellow board paper, edge paper, enterprise unit paper, engineering paper, books and newspapers, etc.

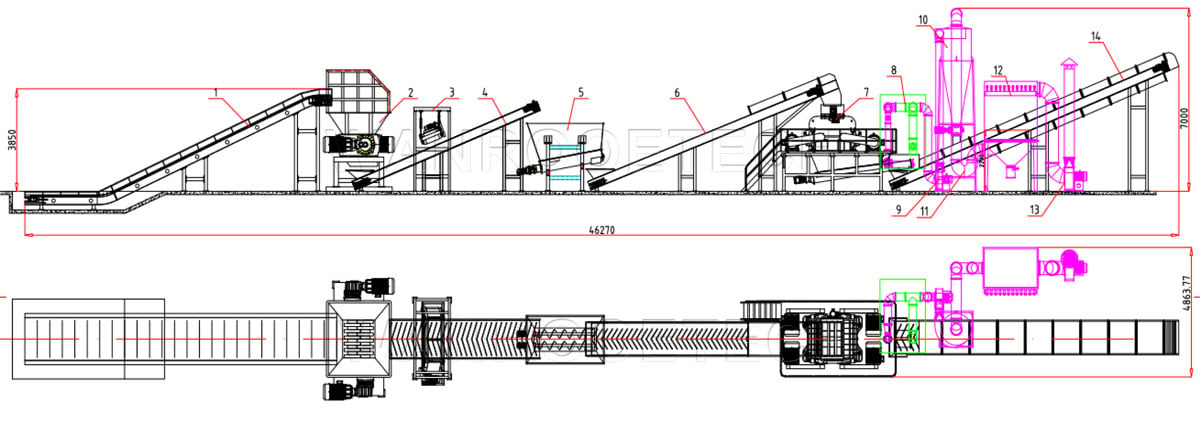

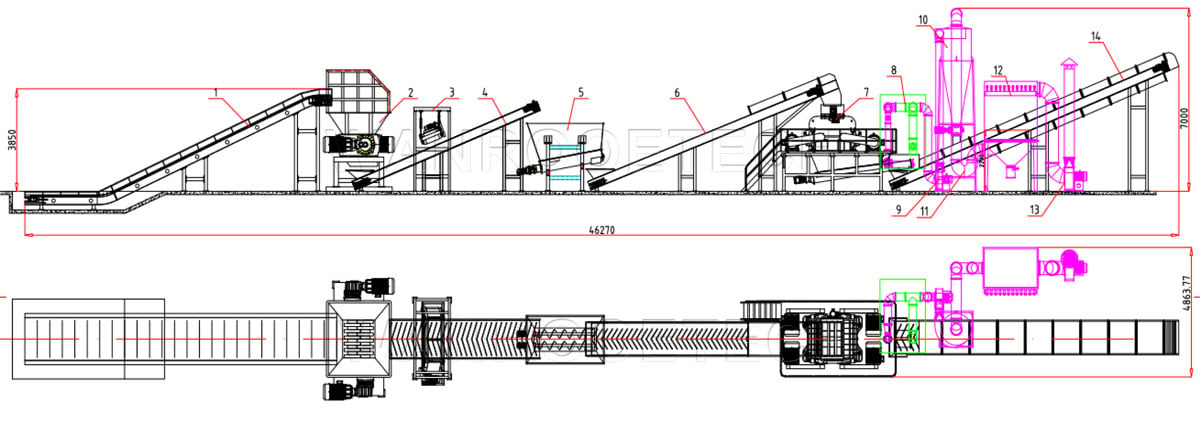

Waste paper recycling pulping machine process:

1. Plate chain conveyor 2. Double-shaft shredder 3. Suspended magnetic separator 4. Shredded material output conveyor (sealed) 5. Double-screw fabric hopper 6. Feeding conveyor for shredder 7. Heavy-duty dust-free compound crusher 8. Dust removal pipe 9. Dust Collector No. 1 10. Cyclone hopper 11. U-shaped fireproof pipe 12. Pulse dust collector 13. Dust collector No. 2 14. Output conveyor No. 3

The waste paper recycling pulping machine provides a dry paper pulp production method for waste paper, which includes the following steps: waste paper pre-treatment, waste paper crushing, dry pulping, pulse dust removal, strong magnetic deironing, and hydraulic packaging.

Plate chain conveyor: The waste paper is first transported to the double-axis shredder by the plate chain conveyor.

Double shaft shredder: The double-axis shredder shreds the waste paper into small pieces for subsequent processing.

Suspended magnetic roller: The suspended magnetic roller is used to remove iron nails, iron filings, and other ferromagnetic impurities from waste paper.

Magnetic separator: The magnetic separator is used to remove plastic, tape, and other non-ferromagnetic impurities from waste paper.

Buffer feed hopper: The buffer feed hopper is used to store the waste paper after being processed by the double-axis shredder, suspended magnetic roller, and magnetic separator.

Variable frequency feeding conveyor: The variable frequency feeding conveyor is used to evenly feed the waste paper to the waste paper pulping machine.

Heavy-duty dust-free compound crusher: The waste paper crusher machine converts waste paper into pulp, and the pulp size can be adjusted according to needs.

Feeding conveyor: The feeding conveyor transports the pulp to the packing machine.

Baler Machine: The baler machine packs the pulp into a certain shape for easy transportation and sale.

Advantages of the waste paper recycling pulping machine

Intelligent Safety System

Equipped with a specially designed fine water mist spray device, active fire prevention is achieved through precise atomization technology, real-time monitoring of high-temperature areas and rapid response, eliminating fire hazards from the source and building multiple safety guarantees for continuous production.

Efficient operation and maintenance design

Adopting a modular process flow, key components support quick disassembly and maintenance, coupled with a visual operation interface, operators can be on duty after simple training, and the overall operating efficiency of the equipment is improved by more than 30%.

Breakthrough in Resource Utilization

Through multi-stage crushing sorting technology, the conversion rate of waste paper can reach up to 95%, and each ton of waste paper can reduce 0.8 cubic meters of landfill space. Combined with an intelligent impurity separation system, the pulp purity reaches over 98%, meeting the standards of high-end papermaking raw materials.

Energy saving and consumption reduction plan

Innovative research and development of dry pulping technology, without the need for external water sources throughout the process, reduces energy consumption by 40% compared to traditional wet pulping. Combined with a variable frequency drive system, the power consumption per unit production capacity is controlled within 70% of the industry standard.

Zero emission environmental protection system

The fully enclosed production chain is equipped with pulse dust removal and activated carbon adsorption devices, with a dust recovery rate of over 99% and volatile organic compound emissions below 50% of EU standards, truly achieving a green cycle in the production process.

Related Equipment:

In order to better provide you with a professional answer, when sending an inquiry, please describe your parameters or technical requirements (such as processing materials, output size, capacity, etc.), we will reply to you as soon as possible!