Industrial Plastic Pulverizer Grinding Machine Application Areas:

Industrial plastic pulverizer grinding machine can be used for powder processing of LLDPE, LDPE, HDPE, PP, PET, PVC, PS, PA, PE, TPU, EVA, ABS, PET, PA6, PA66, PU, Masterbatch, Nylon and other materials. Industrial plastic pulverizer grinding machine is mainly used in producing plastic powder from plastic granules, and scraps. The whole set of plastic pulverizers includes a Cyclone silo, feeding silo, grinding chamber, vibrating sieve, regrinding system, and dust-cleaner. The blade for this plastic pulverizer could be rotor type blade and disk type blade. With the cooling system.

Industrial Plastic Pulverizer Grinding Machine Description:

The WANROOETECH’s new design PNMF-Pro series pulverizing system has its compact design is the perfect fit for the large production user, it uses the dual grinding disc, one disc as primary disc, another is used for fines grinding disc to improve the capacity. This unit, with its integrated PLC controls, assures the highest quality performance with a friendly Human Machine Interface. Up to Double the production rate of a similar size conventional water-cooled pulverizing systems, Lower operating costs through 50% energy savings, Lower-maintenance cost and reduced transportation costs, extended disc life, and Optimal finished material quality.

Industrial plastic pulverizer grinding machine is composed of a high-speed rotating grinding disc and a fixed grinding disc. This PNMF-Pro series of plastic disc pulverizers is a high speed precision grinding equipment, which is used to grind different materials with moderate hardness, impact resistance and friability into powder. It is used to grind different materials of moderate hardness, impact resistance and fragility into powder. The material to be ground is sucked into the grinding chamber through the vertical fixed grinding disc centre, and is cut between the fixed grinding disc and the rotating grinding disc by the centrifugal force generated by the high-speed rotation of the moving grinding disc and thrown to the outer taping. The milled powder is collected by the grinding chamber through the fan and cyclone system. According to the customer's specific grinding needs to choose a single piece of grinding disc or split grinding disc.

Industrial Plastic Pulverizer Grinding Machine Process:

The material enters the cyclone silo→vibration feeding evenly feeds the material to the pulverizer grinding disc→the grinding disc is processed for grinding→the powder is put into the cyclone silo for temporary storage→feeding is controlled by turning off the fan→the vibrating screen screens the material

Industrial Plastic Pulverizer Grinding Machine Feature:

Low drive power – High throughput;

Two Grinding discs, one as primary, another used for fines grinding disc, Greater Output than Comparable Models;

Real-time monitoring of the operation of the grinding mill through the application is more convenient and faster;

Plastic grinding finished product with high quality.

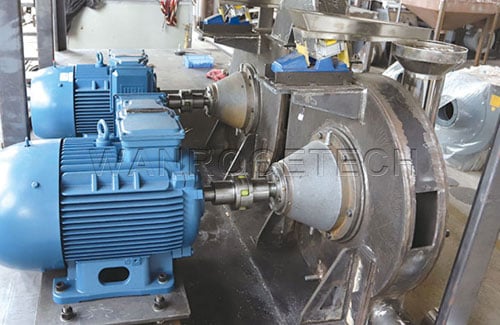

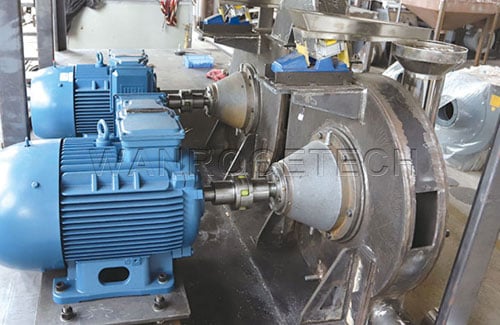

The motor and the main shaft are directly connected by a coupling, the transmission efficiency is about 20% higher than that of the belt connection, and the installation and post-maintenance are convenient.

Compared with the same type of plastic pulverizer, the output is 100%-200% higher under the same power consumption, saving energy consumption.

Air locker discharge, increase dust collection devices, effectively reduce dust pollution, and clean working environment.

Air locker discharge, vibrating screen material selection, and unqualified material automatically back to the mill operation, without manual operation.

the use of wind and water double cooling system, better reduces the working temperature in the body, to ensure uninterrupted grinding operations.

box design humane, open the door, maintenance and replacement of knives, and adjust the gap between the knife disc is convenient and safe.

|  |

| Two Grinding discs, one as primary, another used for fines grinding disc, Greater Output than Comparable Models; | Can be connected to a ventilation cooler; improves cooling efficiency more than 30% |

|  |

| Dust-free design, fully enclosed, pollution-free. | Direct connection design,energy-saving by 20~15%. |

|  |

| Permanent magnet synchronous motor: efficiency increased by 5-15%; | Forced oil circulation system: cooling and lubricating bearings to extend their service life. |

|  |

Mobile internet remote real-time monitoring. | Vibrating Screen, Installation of screen according to the grinding mesh, continuous production, automatic classification and screening, easy to replace.

|